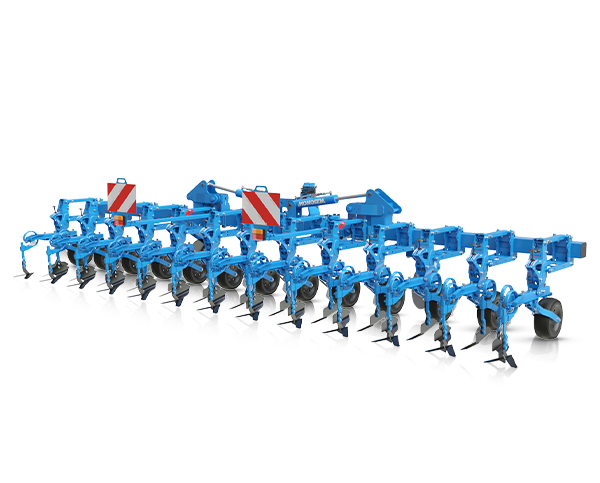

PLANTING TYPE: VEGETABLE CROPS

Lettuce

Onions

Carrots

Endives

etc

NUMBER OF ROWS

2 to 30 rows

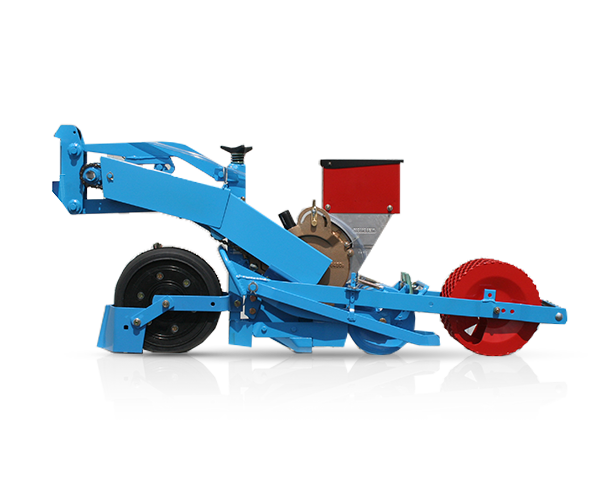

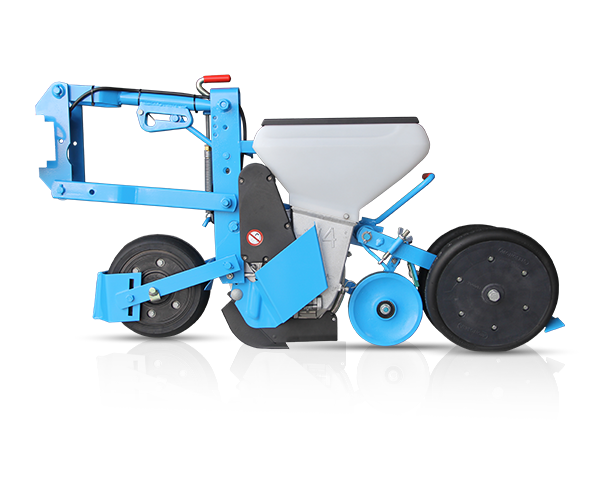

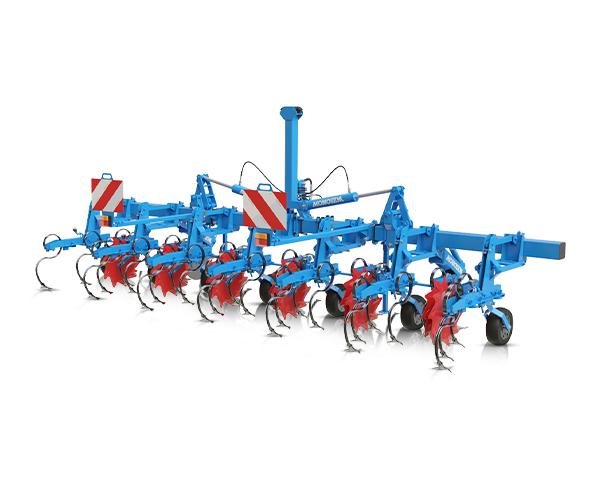

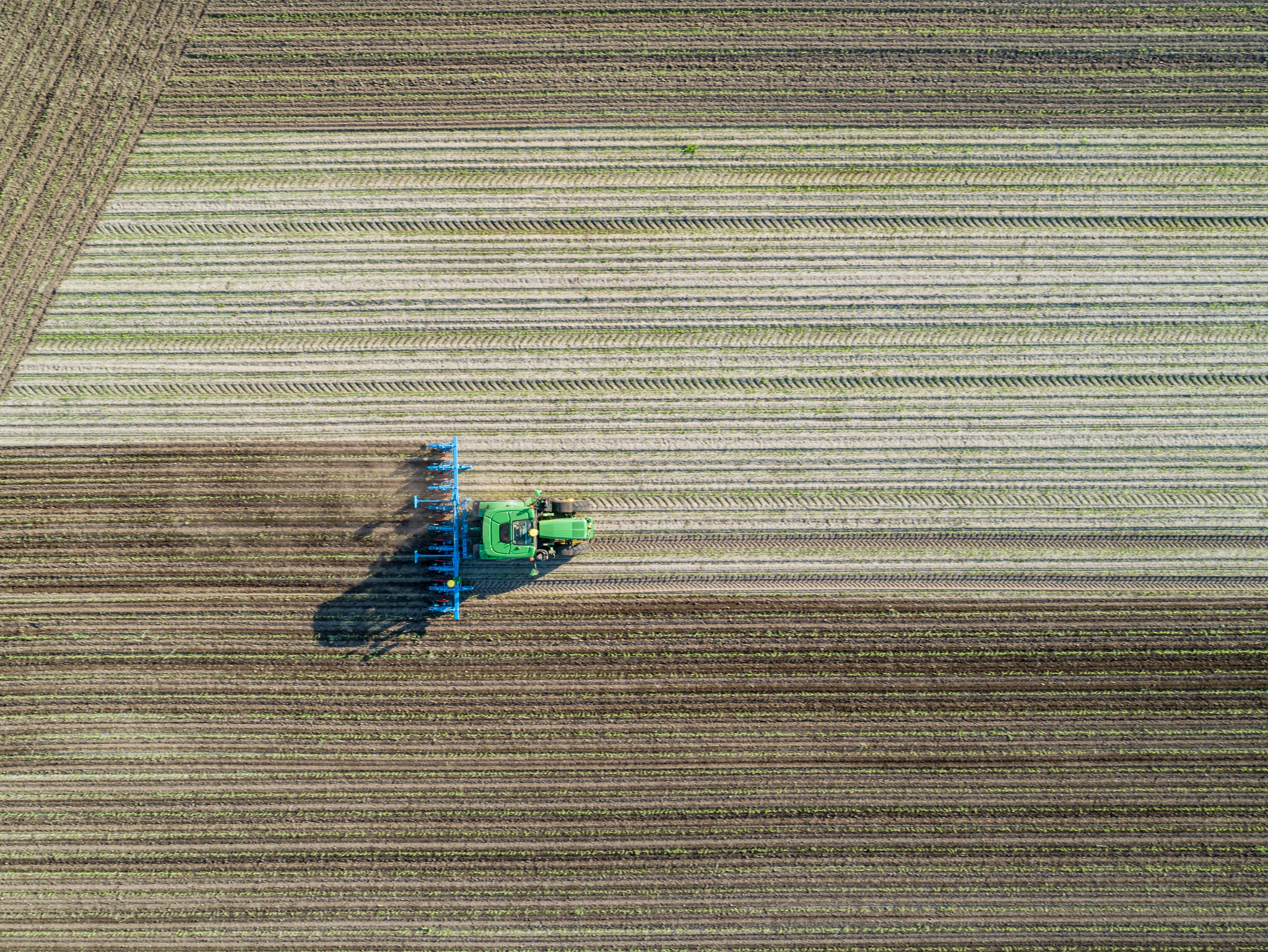

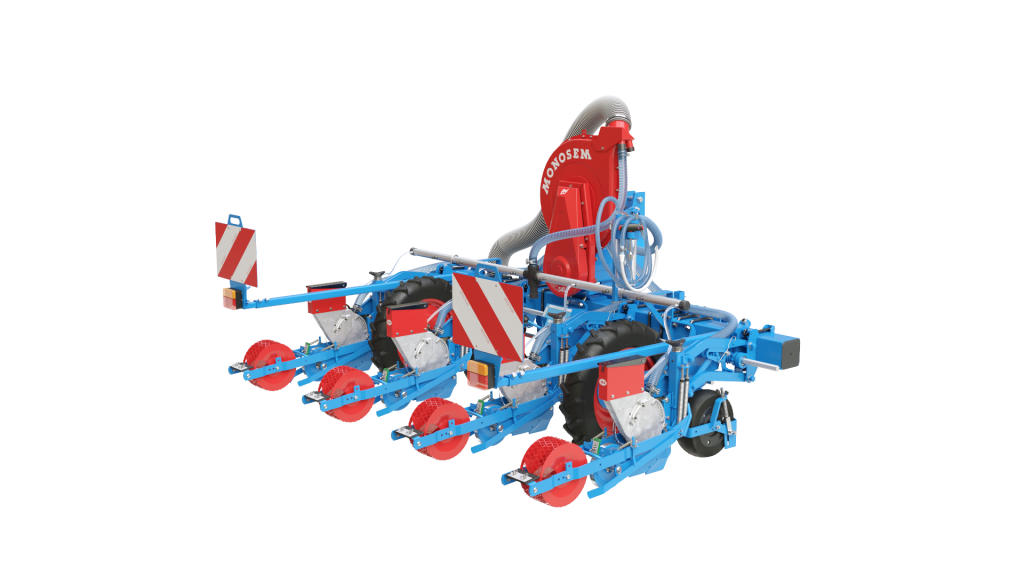

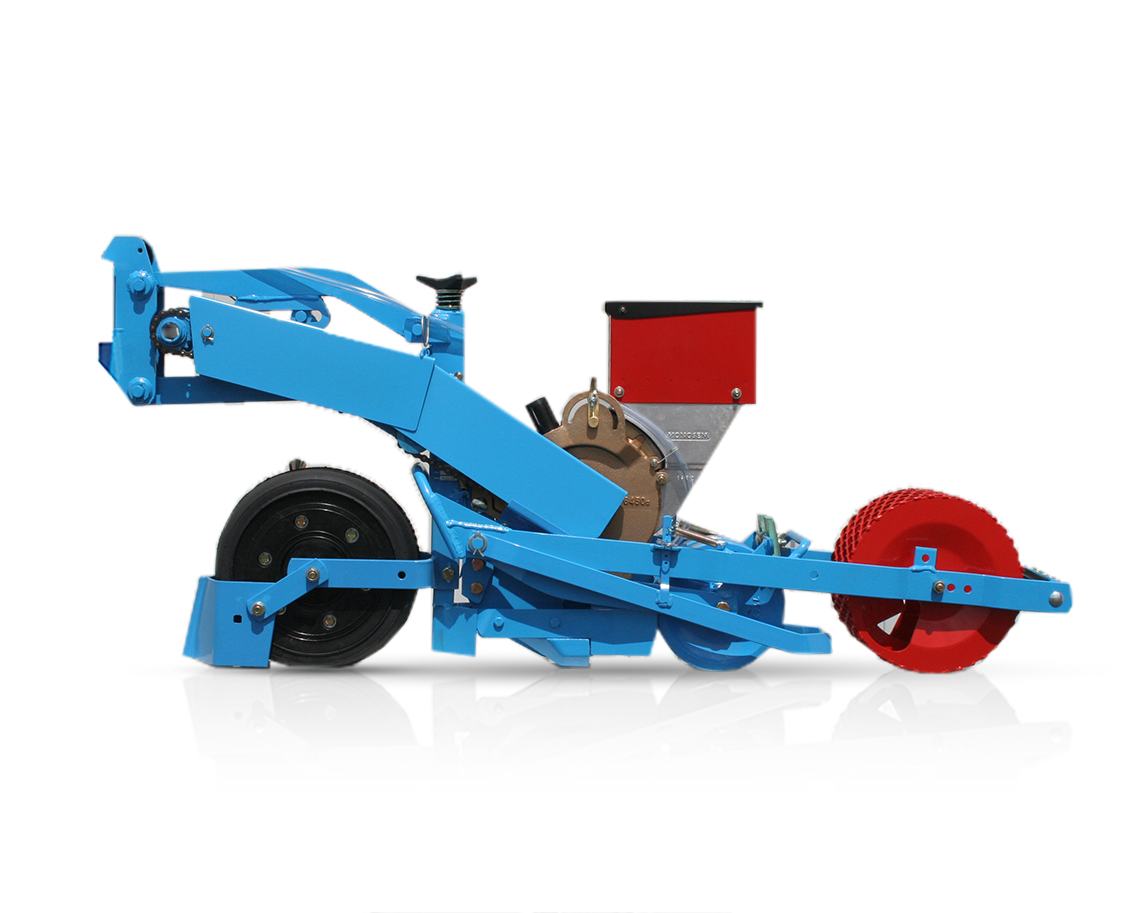

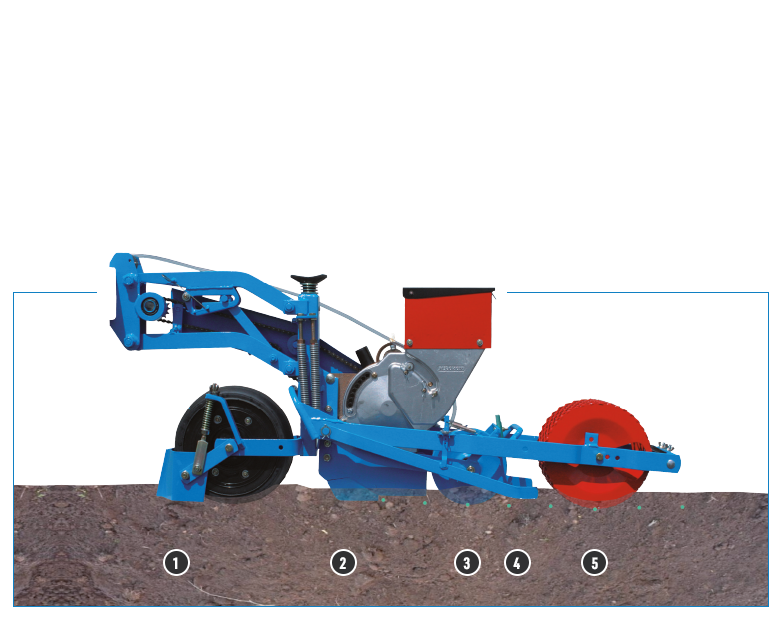

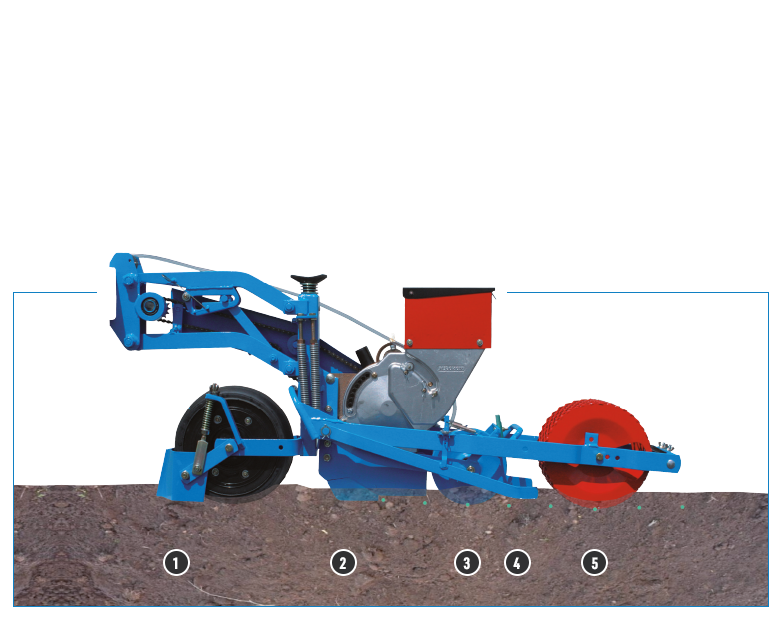

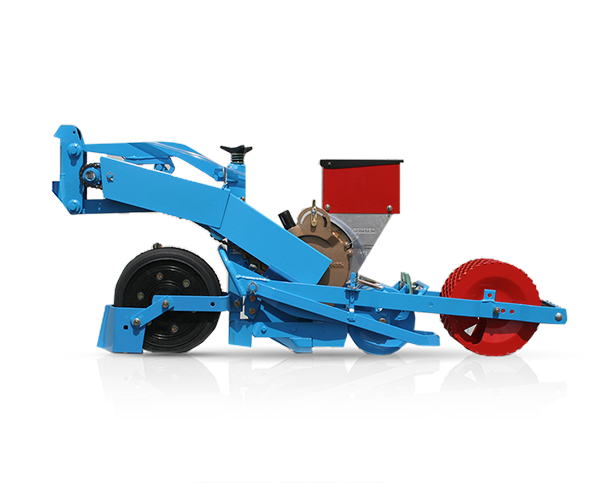

The MS planting unit is specially designed for planting vegetable crops. Its key benefits are excellent seed placement, consistent depth, outstanding shoot emergence, and ease of adjustment. Each unit is capable of planting a wide range of seeds with excellent results.

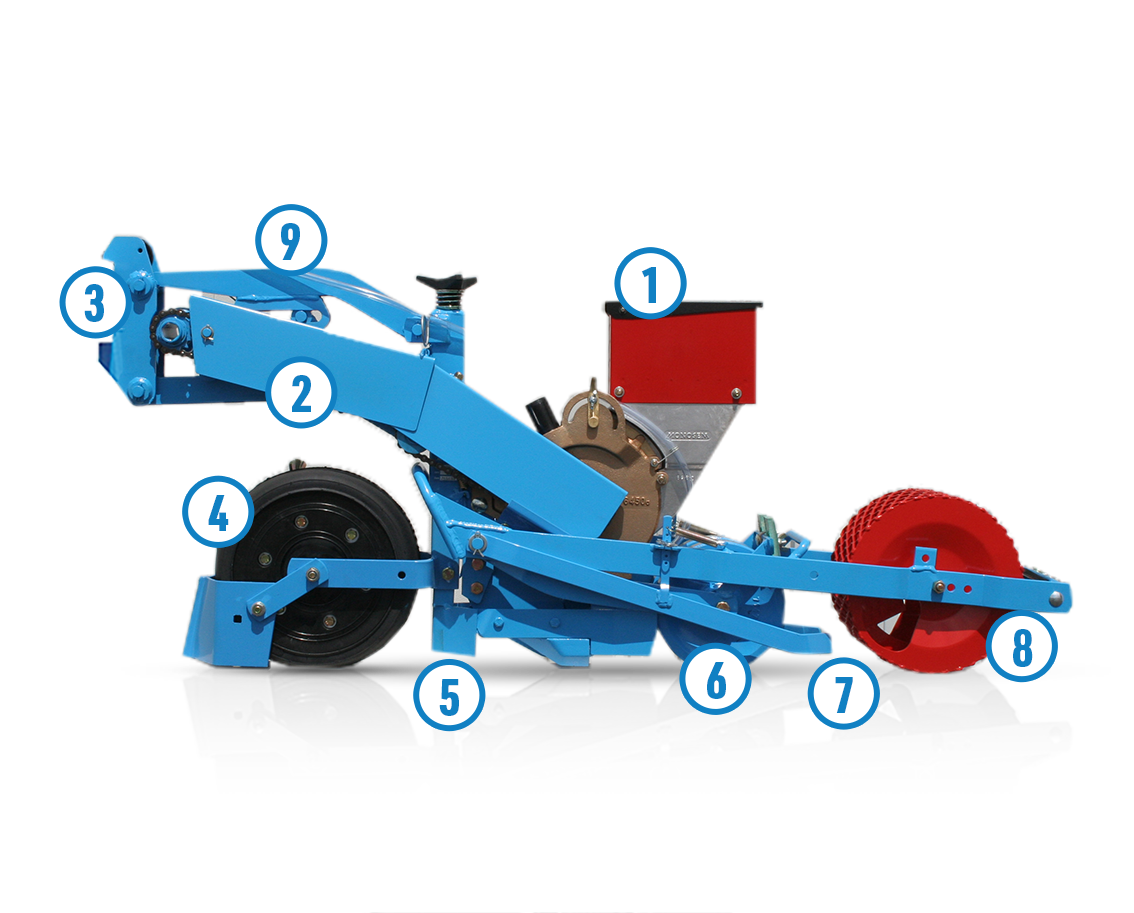

Hopper

MS metering units are supplied as standard with a 1.5L hopper extension. If required, units can be supplied without an extension or with a 3L hopper.

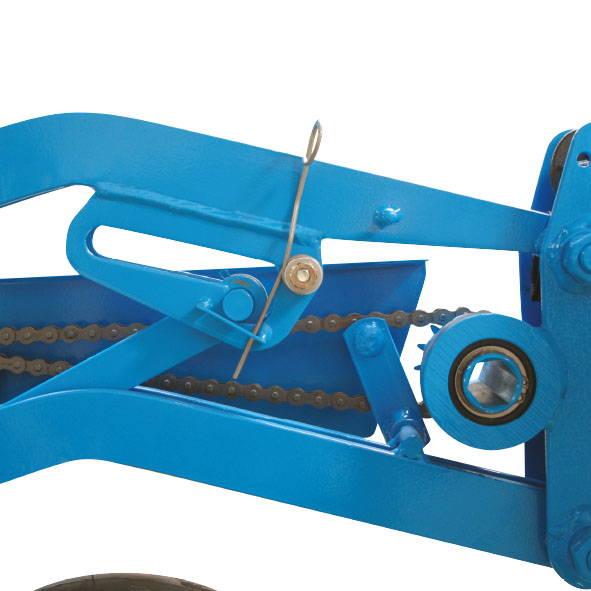

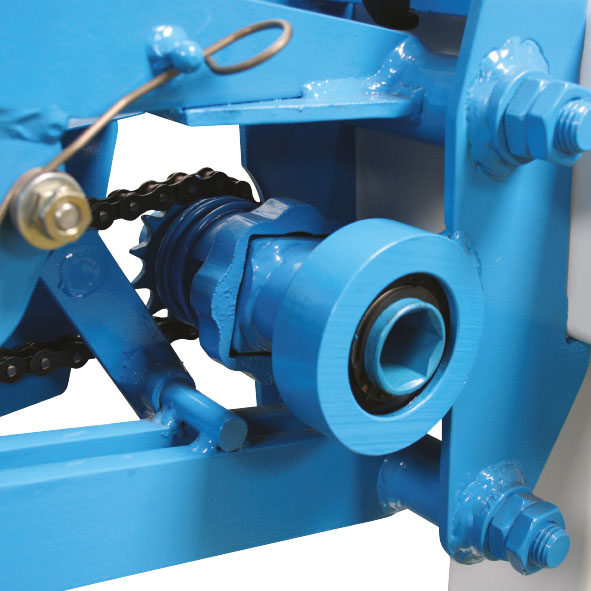

Parallel linkage

The heavy-duty parallel linkage is mounted on replaceable bushings. A locking bolt can be used to keep the unit in its raised position.

Metering unit head

The MS metering unit head is equipped as standard with a manual row cut-off system.

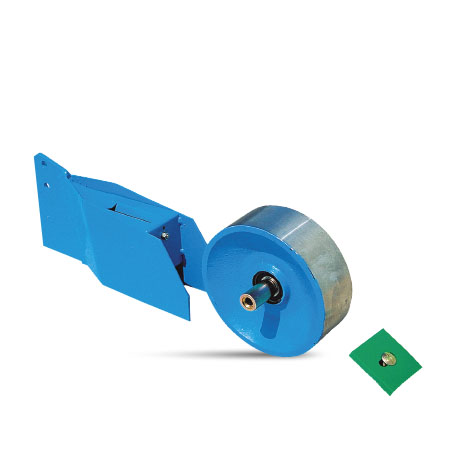

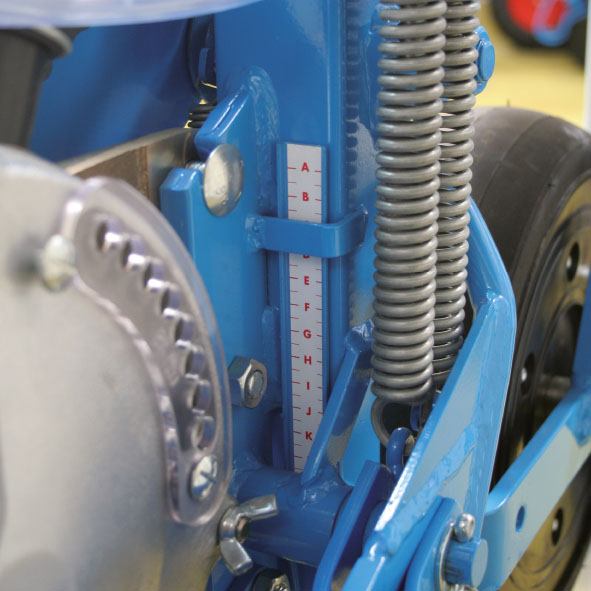

Front gauge wheel

The front gauge wheel ensures optimal planting depth control. Various models of this part mounted on ball bearings are available to meet your requirements. Depth is adjusted using a hand wheel and a scale can be used to accurately check planting depth settings.

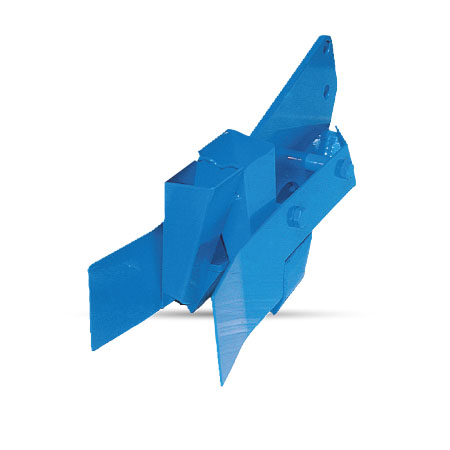

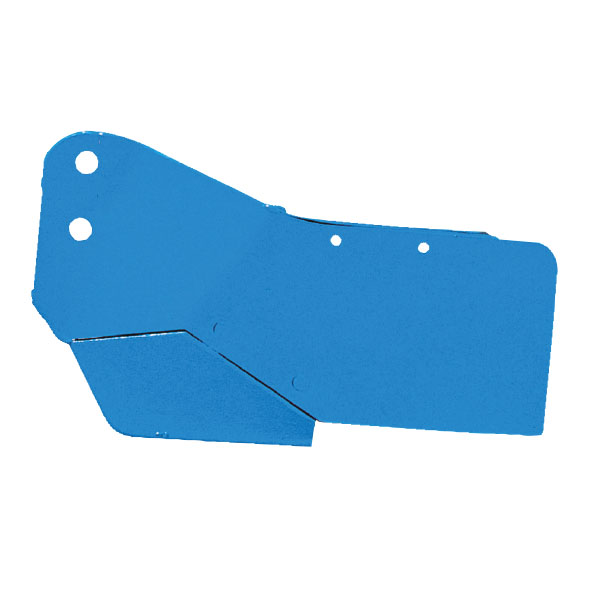

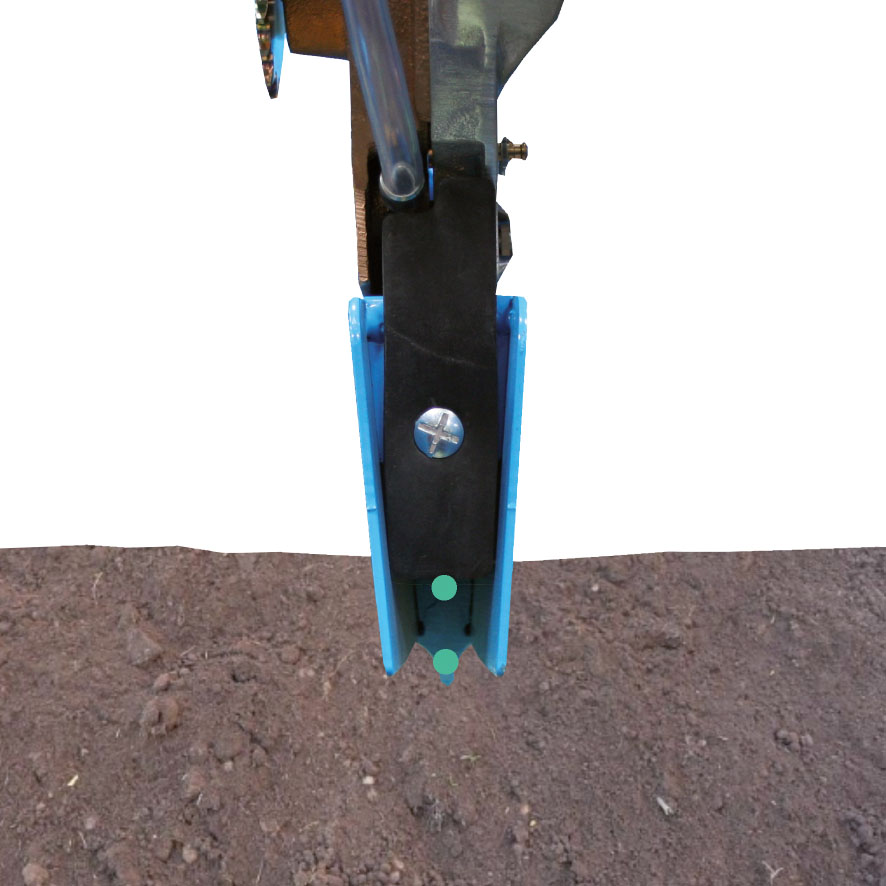

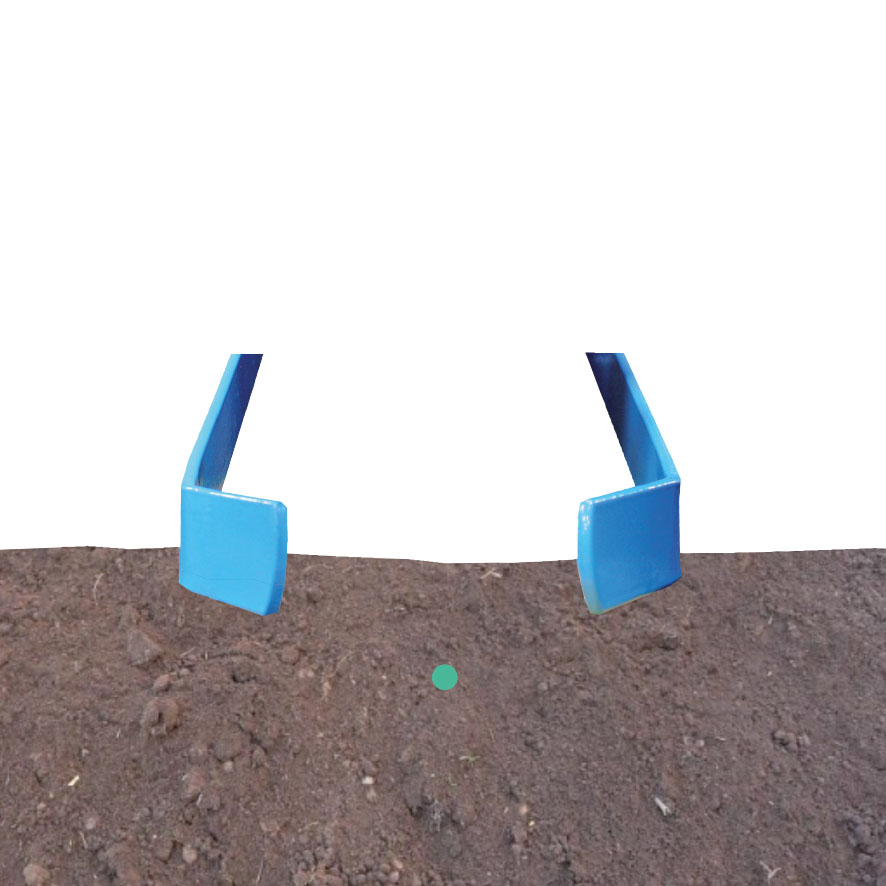

Shoe

MS unit shoes are removable with a replaceable tip and are available in various models to meet your requirements:

- Single line, double lines or strip

- Rounded tip, short wings, extended wings, etc.

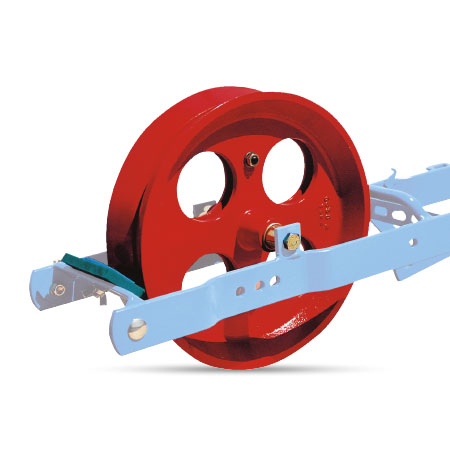

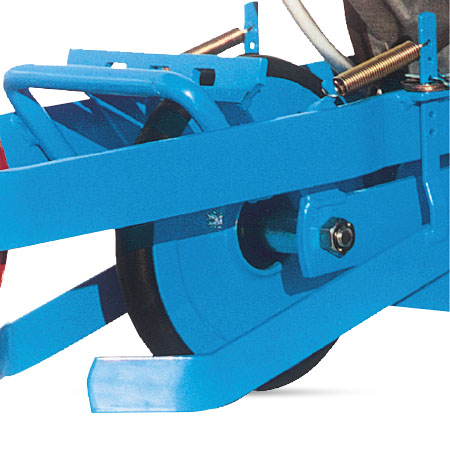

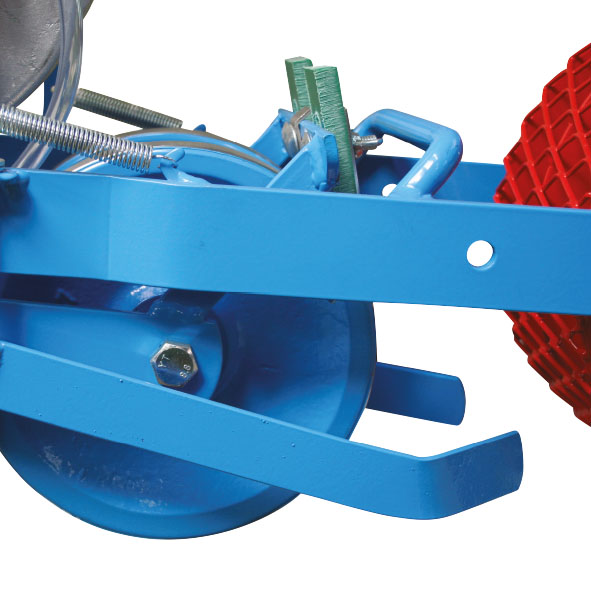

Intermediate press wheel with adjustable pressure

MS units are equipped with intermediate press wheels that press seeds to the furrow bottom, thus improving seed-soil contact. Press wheel ground pressure is adjustable.

Scrapers

These scrapers supplied as standard close the furrow. They are height-adjustable and individually retractable.

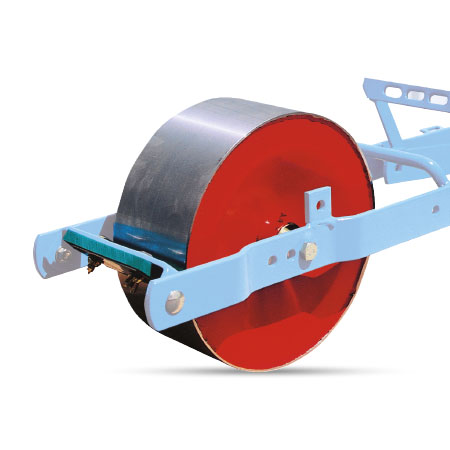

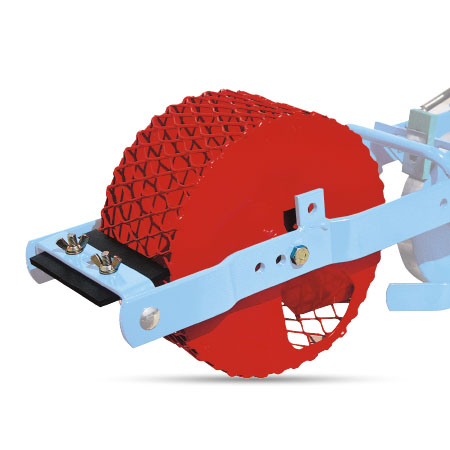

Pressure-adjustable rear closing wheel unit

Various wheel models are available for closing and pressing the furrow. The ground pressure of these wheels is adjustable.

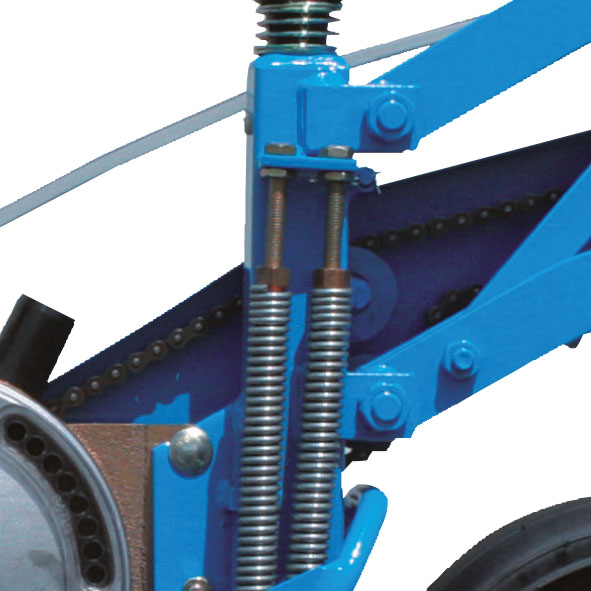

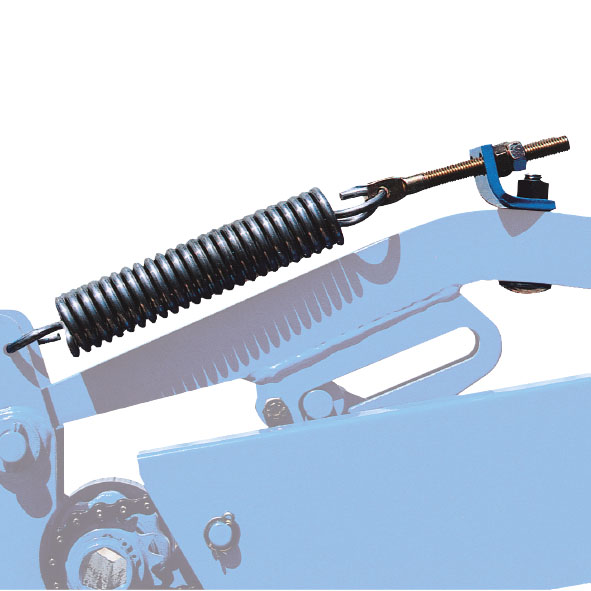

(Optional) Relief spring

For soft soils with low load capacity, a double adjustable relief spring helps relieve the metering unit.

MS metering units are supplied as standard with a 1.5L hopper extension. If required, units can be supplied without an extension or with a 3L hopper.

MS metering units are supplied as standard with a 1.5L hopper extension. If required, units can be supplied without an extension or with a 3L hopper.

The heavy-duty parallel linkage is mounted on replaceable bushings. A locking bolt can be used to keep the unit in its raised position.

The heavy-duty parallel linkage is mounted on replaceable bushings. A locking bolt can be used to keep the unit in its raised position.

The MS metering unit head is equipped as standard with a manual row cut-off system.

The MS metering unit head is equipped as standard with a manual row cut-off system.

The front gauge wheel ensures optimal planting depth control. Various models of this part mounted on ball bearings are available to meet your requirements. Depth is adjusted using a hand wheel and a scale can be used to accurately check planting depth settings.

The front gauge wheel ensures optimal planting depth control. Various models of this part mounted on ball bearings are available to meet your requirements. Depth is adjusted using a hand wheel and a scale can be used to accurately check planting depth settings.

MS unit shoes are removable with a replaceable tip and are available in various models to meet your requirements:

MS unit shoes are removable with a replaceable tip and are available in various models to meet your requirements:

Public

- Single line, double lines or strip

- Rounded tip, short wings, extended wings, etc.

MS units are equipped with intermediate press wheels that press seeds to the furrow bottom, thus improving seed-soil contact. Press wheel ground pressure is adjustable.

These scrapers supplied as standard close the furrow. They are height-adjustable and individually retractable.

Various wheel models are available for closing and pressing the furrow. The ground pressure of these wheels is adjustable.

For soft soils with low load capacity, a double adjustable relief spring helps relieve the metering unit.

We have developed several versions of our MS unit, since all vegetable growers have their own specific requirements.

Just select your requirements to find the ideal MS model for you.

MS PLANTING SYSTEM

The MS metering units' planting system consists of a front gauge wheel to control depth and a shoe for planting.

When you choose Monosem, you can be sure of getting a top-quality product providing an optimal means of planting your vegetable crops.

The clod remover clears the way for the seed line, removing any clods or stones, while the gauge wheel presses the soil and controls depth.

The shoe opens the furrow (or furrows) at a depth defined by the front gauge wheel. In the MS V version, the shoe is fitted with double opener discs that make it easier to work in more challenging conditions.

The pressure-adjustable intermediate press wheel presses seeds to the furrow bottom for rapid and uniform shoot emergence.

The pressure-adjustable intermediate press wheel presses seeds to the furrow bottom for rapid and uniform shoot emergence.

Scrapers (which are retractable if required) scrape fine soil over the seeds.

Scrapers (which are retractable if required) scrape fine soil over the seeds.

The rear wheel closes the furrow around the seeds to ensure optimal germination. In the MS V version, two self-cleaning wheels close the furrow.

A game-changing concept

Inconsistent depth can result in up to 9% lower yield.

Avoid this risk by choosing the Monosem planting system.

- Perfect contour following

- Ultra-precision depth adjustment

- Flawless pressing

- Optimal germination

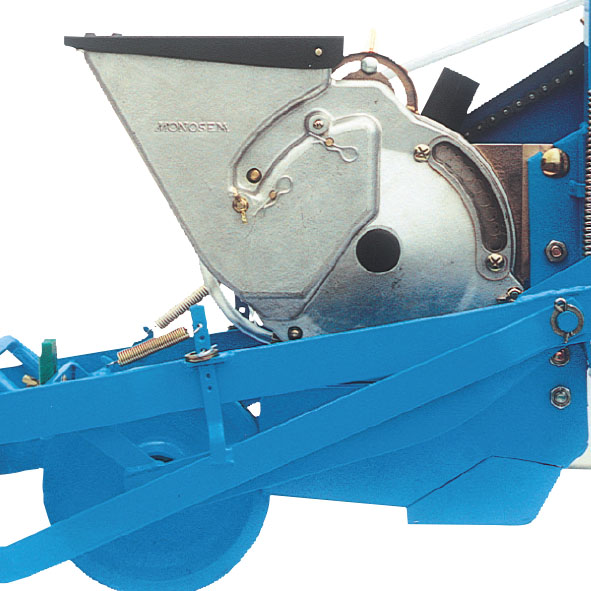

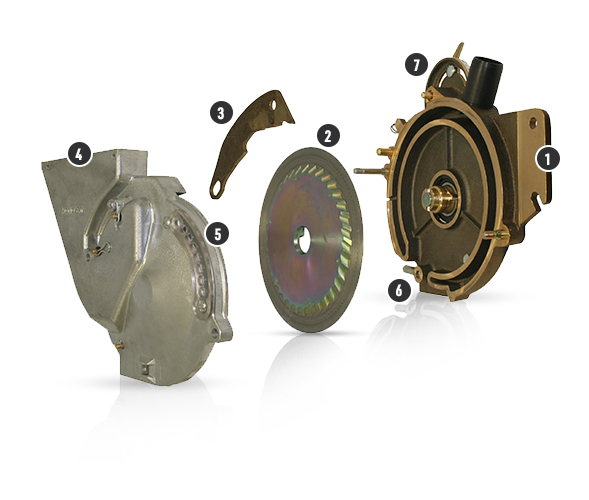

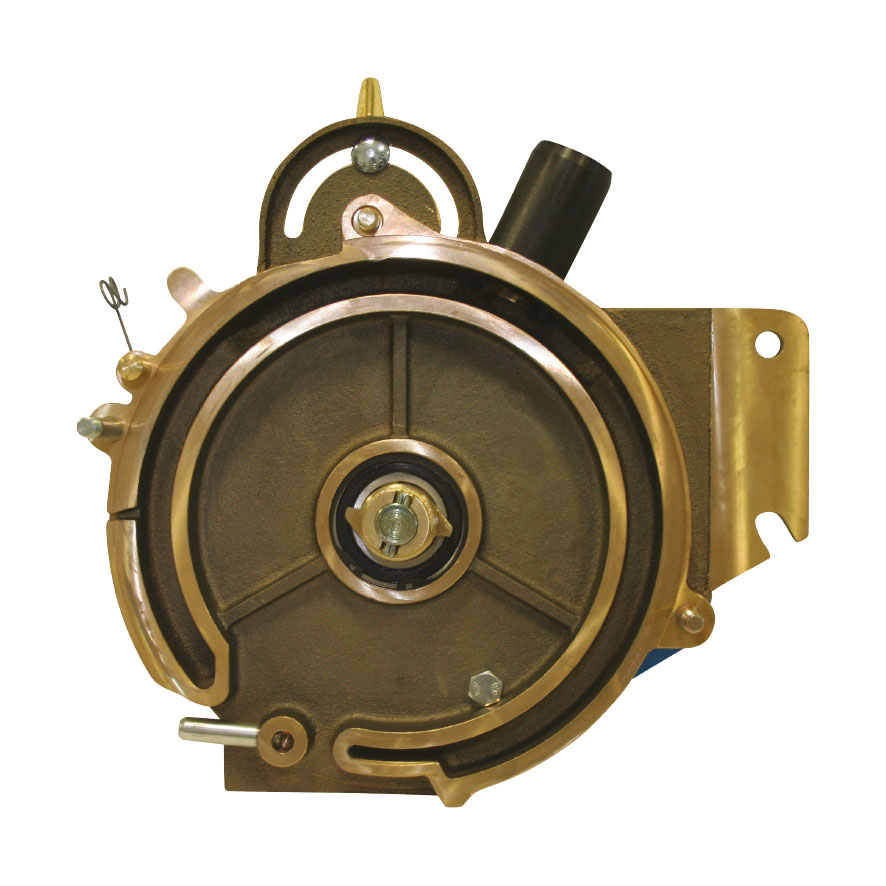

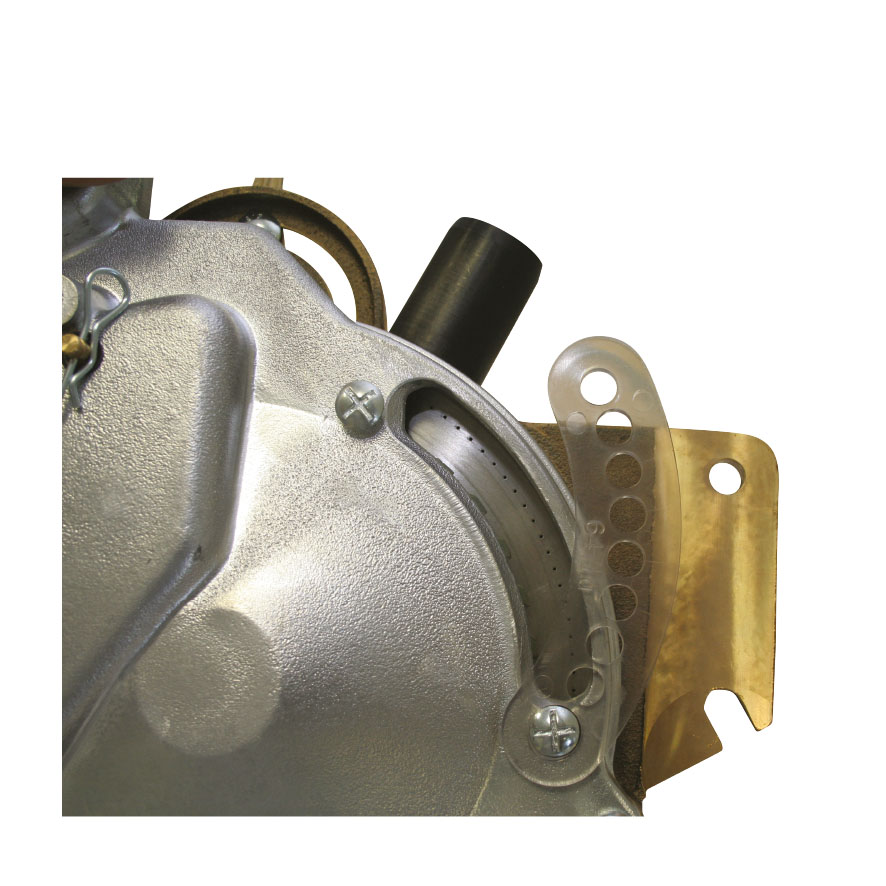

METERING system A GOOD METERING SYSTEM IS ESSENTIAL FOR ENSURING PLANTING QUALITY

That's why Monosem has harnessed all its expertise to offer you an accurate, simple and highly reliable metering system.

The Monosem metering system exhibits manufacturing quality that has earned it a global reputation.

Accept nothing less than this flagship Monosem product for your crops.

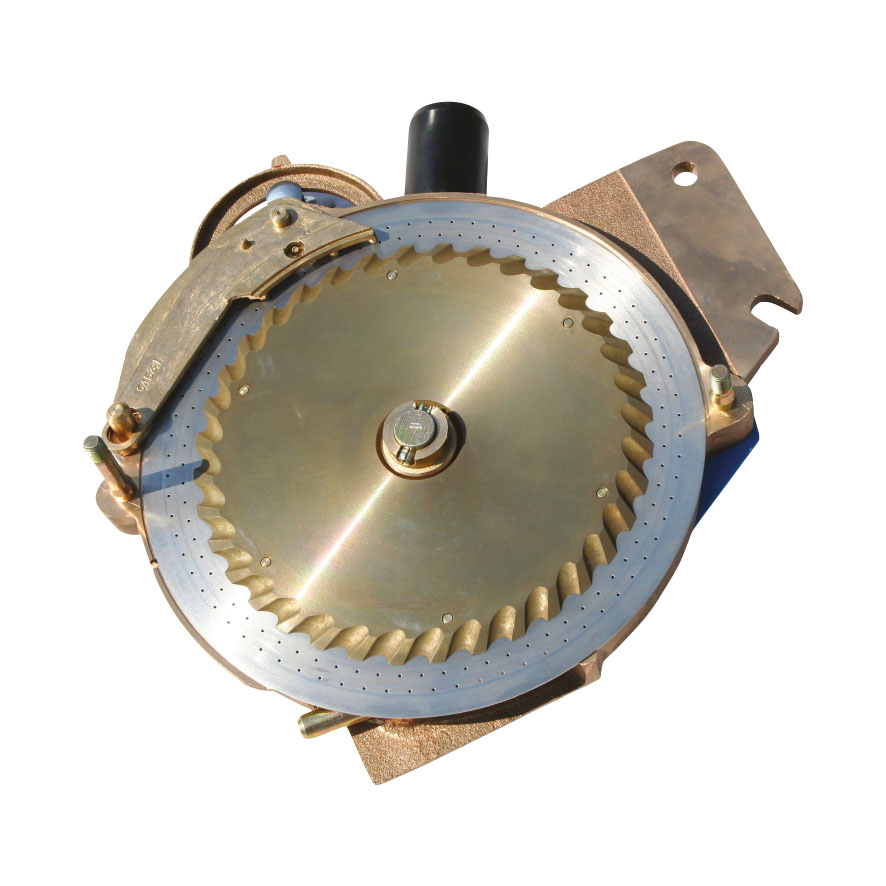

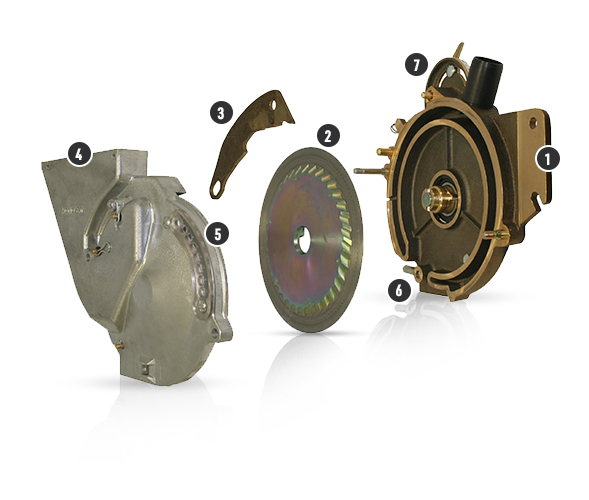

The precision-machined bronze metering box body creates a perfect seal with the disc without any risk of static electricity.

These 1mm thick discs are made of stainless steel. The agitator fixed to the disc strengthens the unit. Discs are easy to change tool-free. A full range of discs is available meeting all small-seed planting requirements.

The bronze singulator prevents any duplicates. A spring on the cover holds the singulator perfectly in place against the disc for optimal metering, even with small seeds.

The cast-iron cover is specially designed for planting with minimal seed reserves. A fibre seal ensures leak-tightness between the disc and cover.

The cast-iron cover is specially designed for planting with minimal seed reserves. A fibre seal ensures leak-tightness between the disc and cover.

The metering system is highly accessible, both for adjustments and monitoring. A transparent window can be used for monitoring metering after the singulator.

After seeds have dropped, a jet of air removes any dust and seed residue that may still be stuck in the disc holes.

Metering is adjusted using just one highly accessible lever on top of the boxes. Due to the quality and precision offered by MS metering boxes, it is possible to apply identical settings to all metering units.

MS metering boxes are capable of both single and double-line planting. Switching between these two options merely involves changing a single-line shoe for a double-line shoe, changing a disc with one line of holes for a disc with two lines of holes, and adding a second scraper.

why choose the

MS planter?

High-precision seed placement

Metering box by Monosem

Easy to adjust

Adjustment hand wheel and depth scale

High-quality shoot emergence

Intermediate press wheel

why choose the

MS planter?

High-precision seed placement

Metering box by Monosem

Easy to adjust

Adjustment hand wheel and depth scale

High-quality shoot emergence

Intermediate press wheel

Microsem's primary objectives are to nurture and protect seeds.

Distributing microgranules requires just as much care and precision as planting.

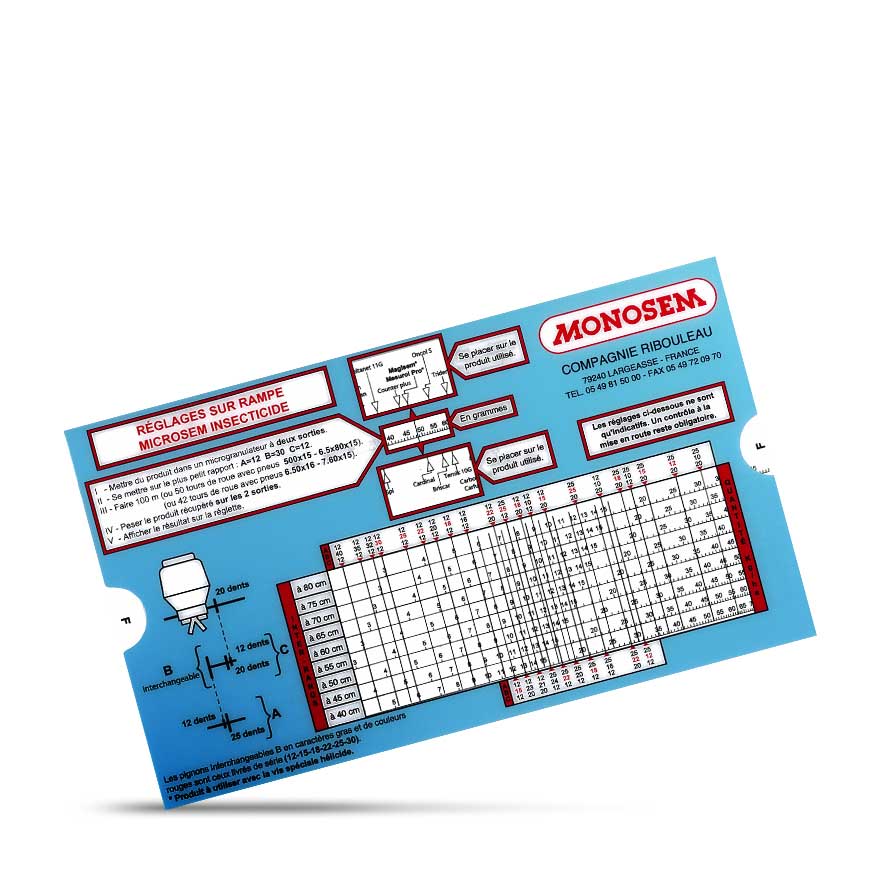

Our auger-based Microsem system ensures consistent distribution of insecticides, molluscicides and even fertilizers.

Microgranules are positioned very close to seeds, protecting them from pests and providing them with all the nutrients they require for uniform shoot emergence.

An 18-ratio gearbox is used to adjust the microgranulators:

An 18-ratio gearbox is used to adjust the microgranulators:

- Using the chart

Our microgranulator is equipped with two drop lines metering different products. One distributes products in the seed line and the other either in front of or behind the closing wheels.

Our microgranulator is equipped with two drop lines metering different products. One distributes products in the seed line and the other either in front of or behind the closing wheels.

Using the hatches and chute, it's quick and easy to empty any remaining products.

Using the hatches and chute, it's quick and easy to empty any remaining products.

The microgranules contained in the hopper are taken up by 2 augers. Agitators ensure an even supply to these augers. A finger wheel then distributes the product consistently in the drop lines.

Insecticide: 3 to 25kg/ha for inter-row spacing of 75cm

Molluscicide: 3 to 10kg/ha for inter-row spacing of 75cm

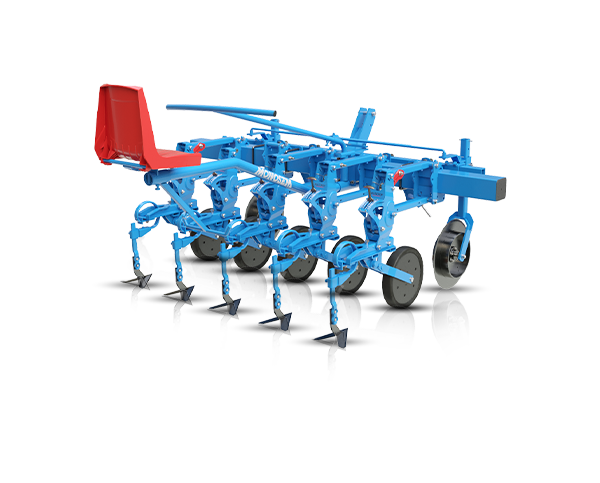

FERTILIZING SYSTEMS

With our full range of standard and high-capacity fertilizers, we can offer a sturdy fertilizer system that suits your planting conditions perfectly.

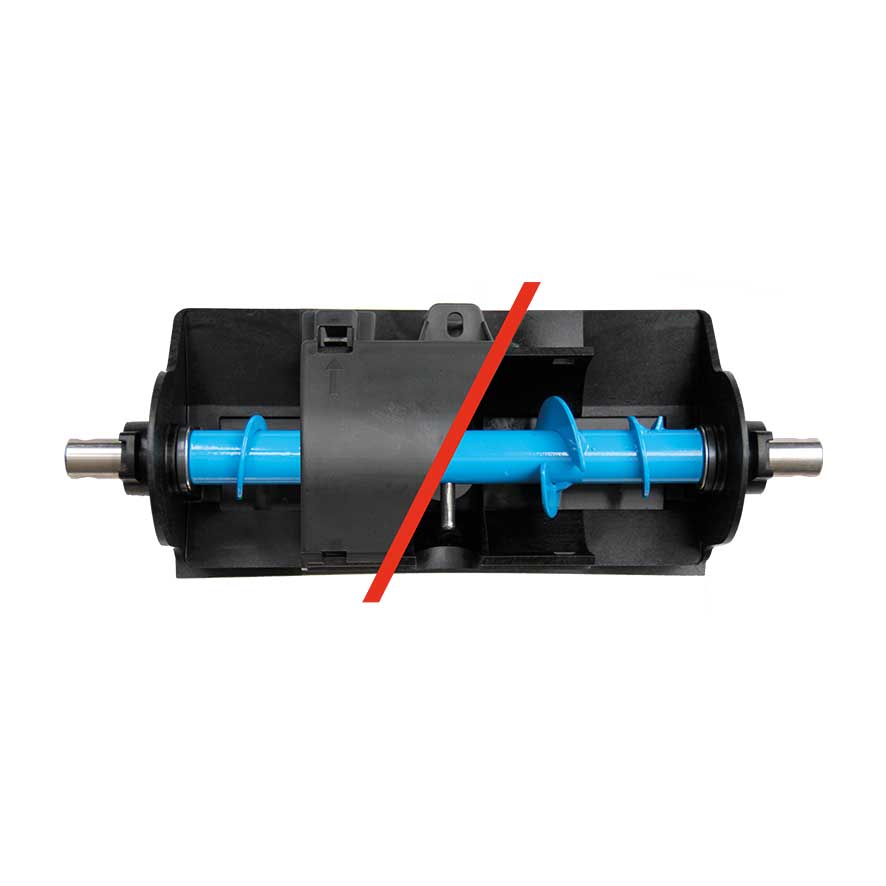

Fertilizer is evenly distributed using a system combining auger-based metering and agitators.

Stainless-steel augers with different pitches are available, ensuring that exactly the required quantity is metered.

Hoppers are available in various capacities and can be mounted on rigid and telescopic frames.

Hoppers are available in various capacities and can be mounted on rigid and telescopic frames.

Electrically or mechanically driven versions are available, supporting you throughout planting and ensuring unrivalled precision

Just choose the capacity you need! Our high-capacity hoppers have a wide opening and offer reliable metering in all conditions.

Just choose the capacity you need! Our high-capacity hoppers have a wide opening and offer reliable metering in all conditions.

A 12-ratio gearbox is used to adjust the quantity of fertilizer metered during planting.

A 12-ratio gearbox is used to adjust the quantity of fertilizer metered during planting.

- Using the chart

- With tines: replaceable tip

- With tines: replaceable tip

- Double discs (or reinforced double discs): versatile and more suitable for low-till conditions

Fertilizer is evenly distributed using a system combining auger-based metering and agitators. Stainless-steel augers with different pitches are available, ensuring that exactly the required quantity is metered.

The "standard" augers (A) are blue and meter 80 to 350kg/ha of fertilizer at inter-row spacing of 75cm.

The "high-output" augers (B) are red and meter 160 to 700kg/ha of fertilizer at inter-row spacing of 75cm.

If our mounted hoppers do not meet your requirements, take a look at our front fertilizers and the Monosem CART.

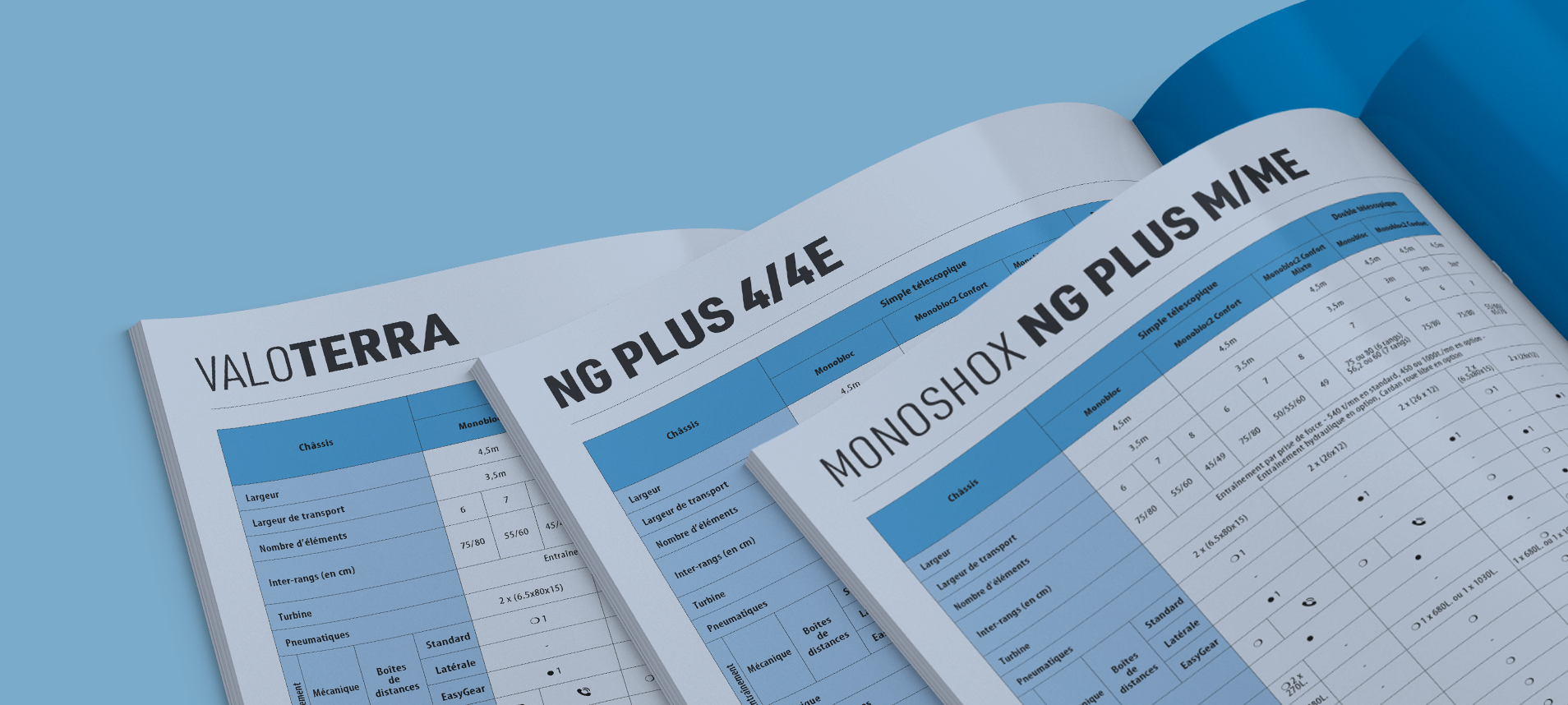

A WIDE RANGE of frames

Monosem supplies a full range of frames that are both durable and flexible to meet all your requirements.

With components including wheel units, a turbofan and seed spacing gearbox, choose a frame to suit your working practices.

MS planter

FEATURES

PLANTING TYPE: VEGETABLE CROPS

Lettuce

Onions

Carrots

Endives

etc.

TILLAGE

Traditional

NUMBER OF ROWS

2 to 30 rows

INTER-ROW SPACING

14 to 190cm

DRIVE

Mechanical

PLANTING TYPE: VEGETABLE CROPS

Lettuce

Onions

Carrots

Endives

etc.

TILLAGE

Traditional

NUMBER OF ROWS

2 to 30 rows

INTER-ROW SPACING

14 to 190cm

DRIVE

Mechanical

Are you INTERESTED?

Don't delay a second longer

Documents

Download our manuals and brochures to find out more about our MS planters