ISOBUS SOLUTIONS

Monosem supplies ISOBUS solutions providing users with a wide range of features including seed monitoring, planting density adjustment and GPS-guided automatic row cut-offs. Monosem was awarded Agricultural Industry Electronics Foundation (AEF) certification for the control units used with its electric planters (S8000E) and front fertilizers (F800E). This certification guarantees maximum compatibility between ISOBUS-enabled tractors and Monosem tools. Our planters are certified for the following features: UT (Universal Terminal), TC-BAS (Task Controller Basic), TC-SC (Task Controller Section Control) and TC-GEO (Task Controller Geo-Based).

ISOBUS TERMINALS

Monosem puts new technologies within everyone's reach to increasingly facilitate the planting process. ISOBUS terminals offer users features such as GPS-guided row cut-offs to constantly improve operating precision.

connection SYSTEM

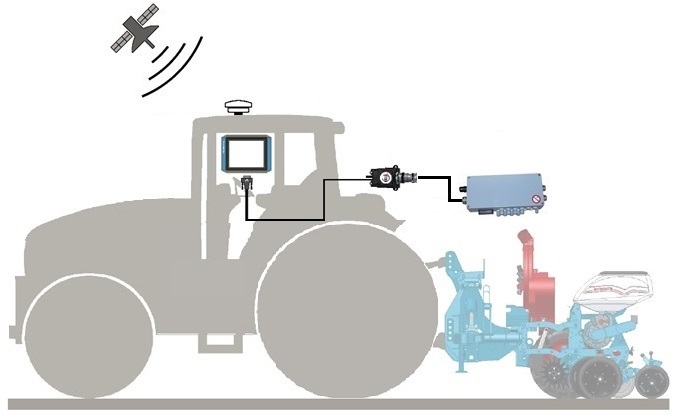

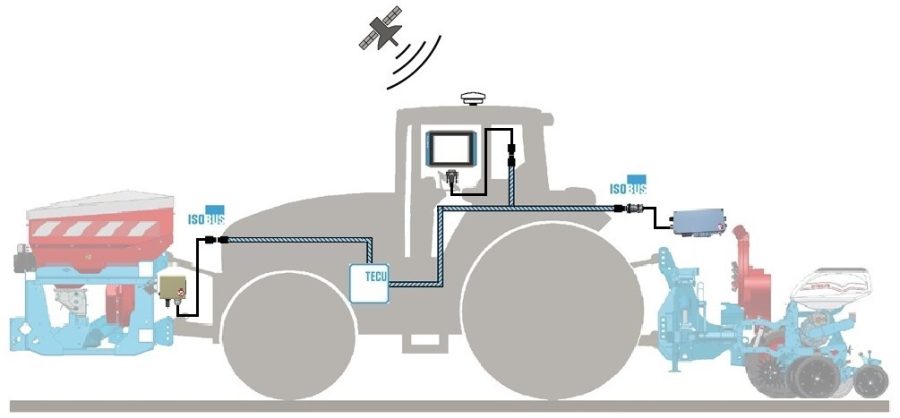

To enable data exchange between the ISOBUS console and the ISOBUS planter, the rear ISOBUS wiring harness with the following reference number must be installed on the tractor: 10230352. A GPS antenna can be connected to the ISOBUS console in order to use the TC-SC (GPS-guided row cut-off system) and TC-GEO (variable rate control by prescription map) functions.

To enable data exchange between the ISOBUS console and the ISOBUS planter, the rear ISOBUS wiring harness with the following reference number must be installed on the tractor: 10230352. A GPS antenna can be connected to the ISOBUS console in order to use the TC-SC (GPS-guided row cut-off system) and TC-GEO (variable rate control by prescription map) functions.

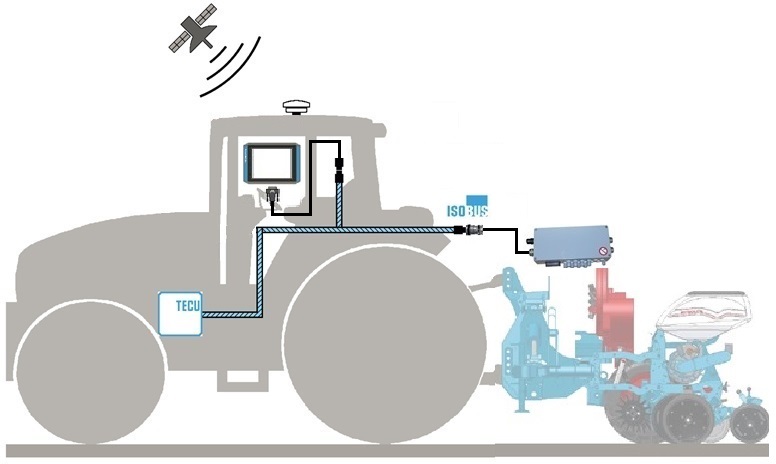

To enable data exchange between the ISOBUS console and the ISOBUS planter, the in-cab wiring harness with the following reference number must be installed on the tractor: 10239036. A GPS antenna can be connected to the ISOBUS console in order to use the TC-SC (GPS-guided row cut-off system) and TC-GEO (variable rate control by prescription map) functions.

To enable data exchange between the ISOBUS console and the ISOBUS planter, the in-cab wiring harness with the following reference number must be installed on the tractor: 10239036. A GPS antenna can be connected to the ISOBUS console in order to use the TC-SC (GPS-guided row cut-off system) and TC-GEO (variable rate control by prescription map) functions.

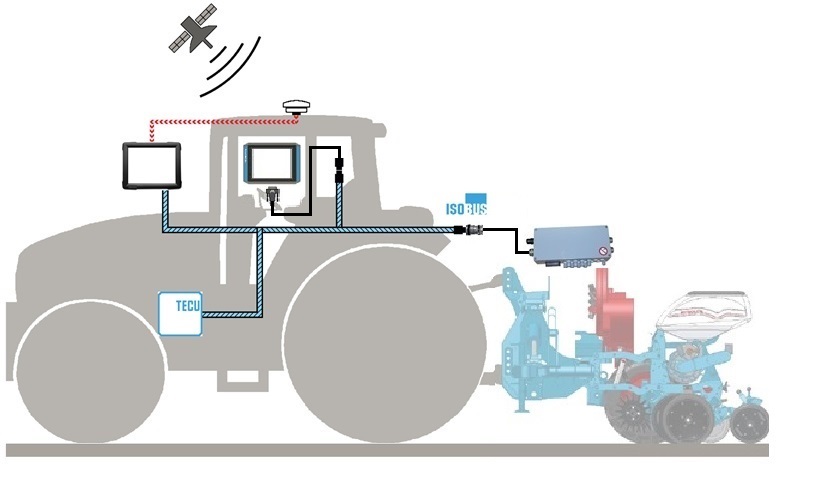

To enable data exchange between ISOBUS console 2 and the ISOBUS planter, the in-cab wiring harness with the following reference number must be installed on the tractor: 10239036. ISOBUS console 1 is the fixed ISOBUS console for the ISOBUS tractor. In this example, ISOBUS console 1 controls the GPS-guided row cut-off system and ISOBUS console 2 only displays the planter's ISOBUS software. A GPS antenna can also be connected to ISOBUS console 2 in order to use the TC-SC (GPS-guided row cut-off system) and TC-GEO (variable rate control by prescription map) functions.

To enable data exchange between ISOBUS console 2 and the ISOBUS planter, the in-cab wiring harness with the following reference number must be installed on the tractor: 10239036. ISOBUS console 1 is the fixed ISOBUS console for the ISOBUS tractor. In this example, ISOBUS console 1 controls the GPS-guided row cut-off system and ISOBUS console 2 only displays the planter's ISOBUS software. A GPS antenna can also be connected to ISOBUS console 2 in order to use the TC-SC (GPS-guided row cut-off system) and TC-GEO (variable rate control by prescription map) functions.

To enable data exchange between the ISOBUS front-mounted hopper and the ISOBUS planter, the ISOBUS cables for these two equipment items must simply be connected to the tractor's front and rear ISOBUS connectors. In this case, both sets of ISOBUS software can be used on the same ISOBUS console. Planter position and speed data can be pooled to facilitate use of the front-mounted hopper.

To enable data exchange between the ISOBUS front-mounted hopper and the ISOBUS planter, the ISOBUS cables for these two equipment items must simply be connected to the tractor's front and rear ISOBUS connectors. In this case, both sets of ISOBUS software can be used on the same ISOBUS console. Planter position and speed data can be pooled to facilitate use of the front-mounted hopper.

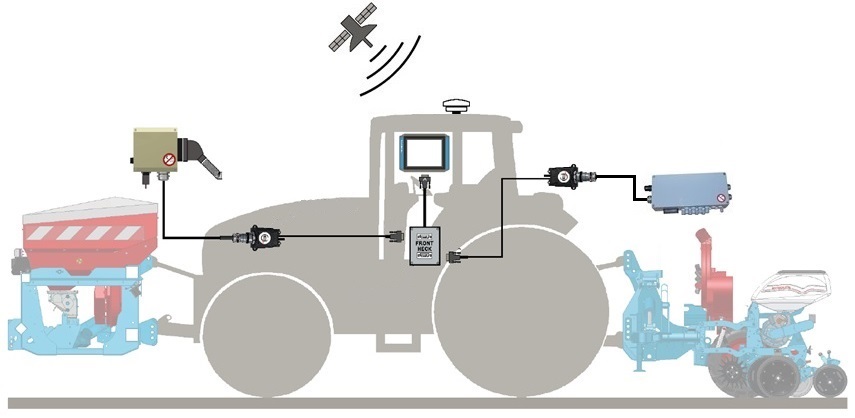

To enable data exchange between the ISOBUS front-mounted hopper and ISOBUS planter on a tractor that is not equipped with ISOBUS, the following must be installed: - a front ISOBUS wiring harness with reference number: 10230354 - a rear ISOBUS wiring harness with reference number: 10230352 - a "Front/Rear" unit with reference number: 10230335. In this case, both sets of ISOBUS software can be used on the same ISOBUS console. Planter position and speed data can be pooled to facilitate use of the front-mounted hopper.

To enable data exchange between the ISOBUS front-mounted hopper and ISOBUS planter on a tractor that is not equipped with ISOBUS, the following must be installed: - a front ISOBUS wiring harness with reference number: 10230354 - a rear ISOBUS wiring harness with reference number: 10230352 - a "Front/Rear" unit with reference number: 10230335. In this case, both sets of ISOBUS software can be used on the same ISOBUS console. Planter position and speed data can be pooled to facilitate use of the front-mounted hopper.

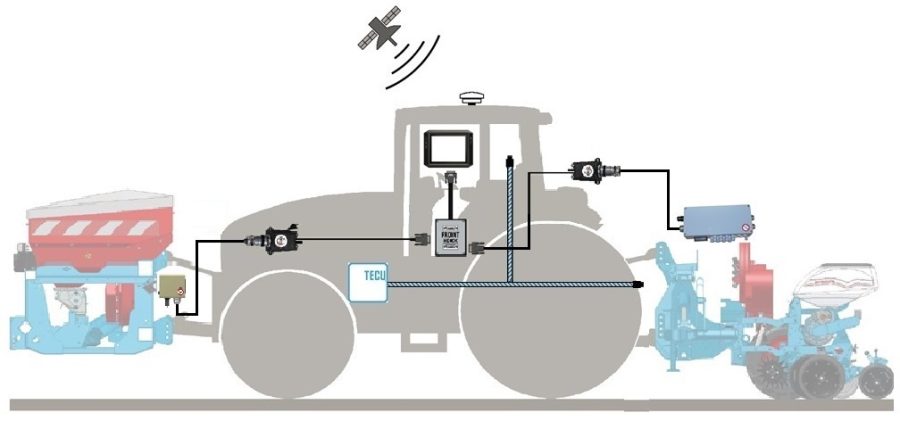

In this specific instance, it is not possible to connect the Monosem front ISOBUS wiring harness to a tractor already equipped with a rear ISOBUS connector. To enable data exchange between the ISOBUS front-mounted hopper and ISOBUS planter on a tractor that is equipped with a rear ISOBUS connector, the following must be installed: - a front ISOBUS wiring harness with reference number: 10230354 - a rear ISOBUS wiring harness with reference number: 10230352 - a "Front/Rear" unit with reference number: 10230335.

In this specific instance, it is not possible to connect the Monosem front ISOBUS wiring harness to a tractor already equipped with a rear ISOBUS connector. To enable data exchange between the ISOBUS front-mounted hopper and ISOBUS planter on a tractor that is equipped with a rear ISOBUS connector, the following must be installed: - a front ISOBUS wiring harness with reference number: 10230354 - a rear ISOBUS wiring harness with reference number: 10230352 - a "Front/Rear" unit with reference number: 10230335.