CROP TYPE

Maize Sugarbeet

Sunflower Rapeseed

Soya Beans

NUMBER OF ROWS

6 to 12 rows

INTER-ROW SPACING

45cm to 80cm

TILLAGE

Traditional

Low till

No till

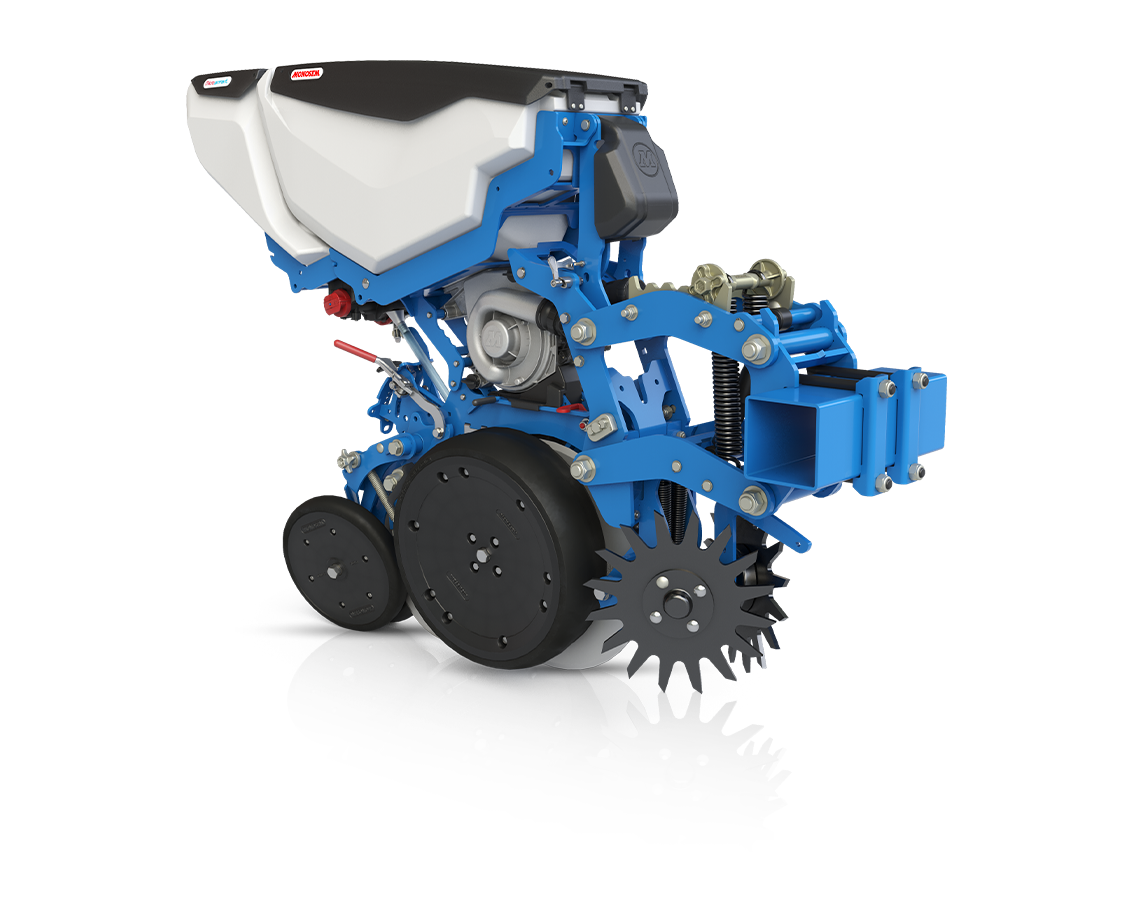

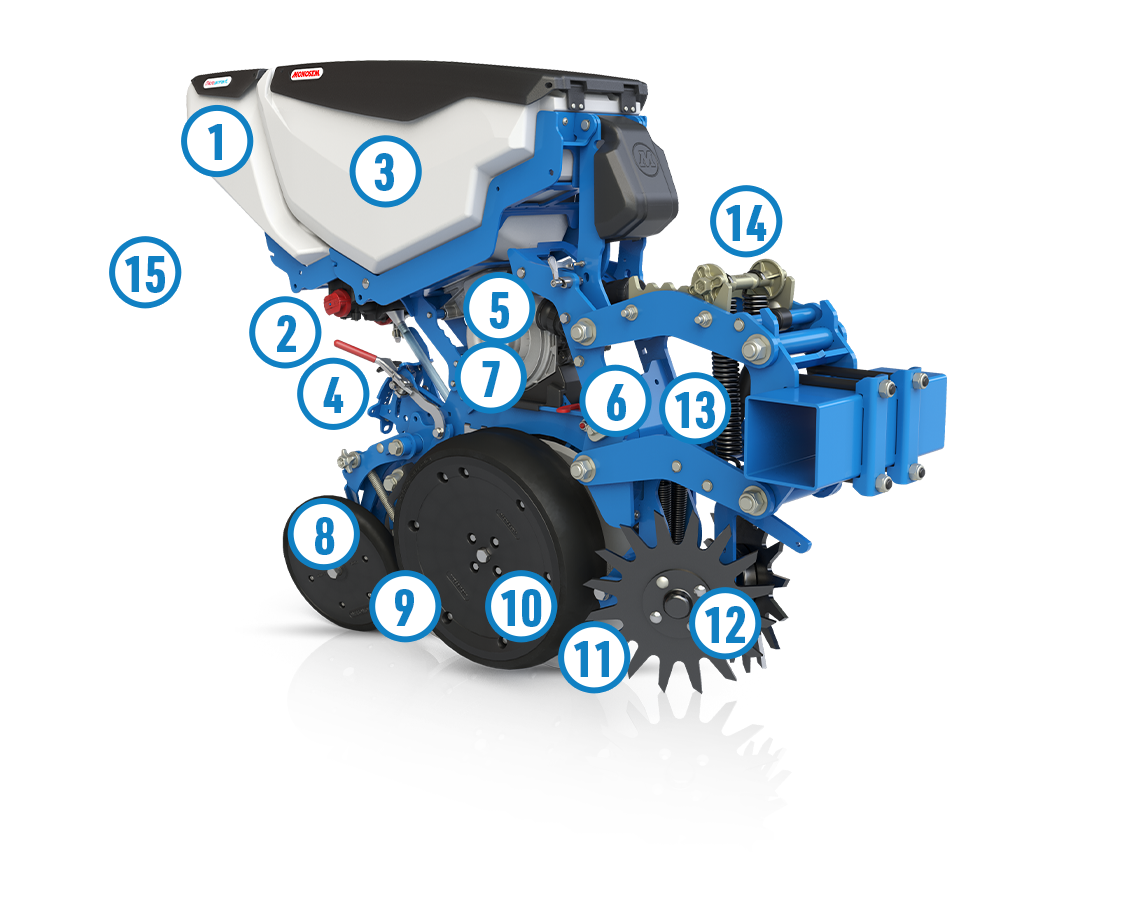

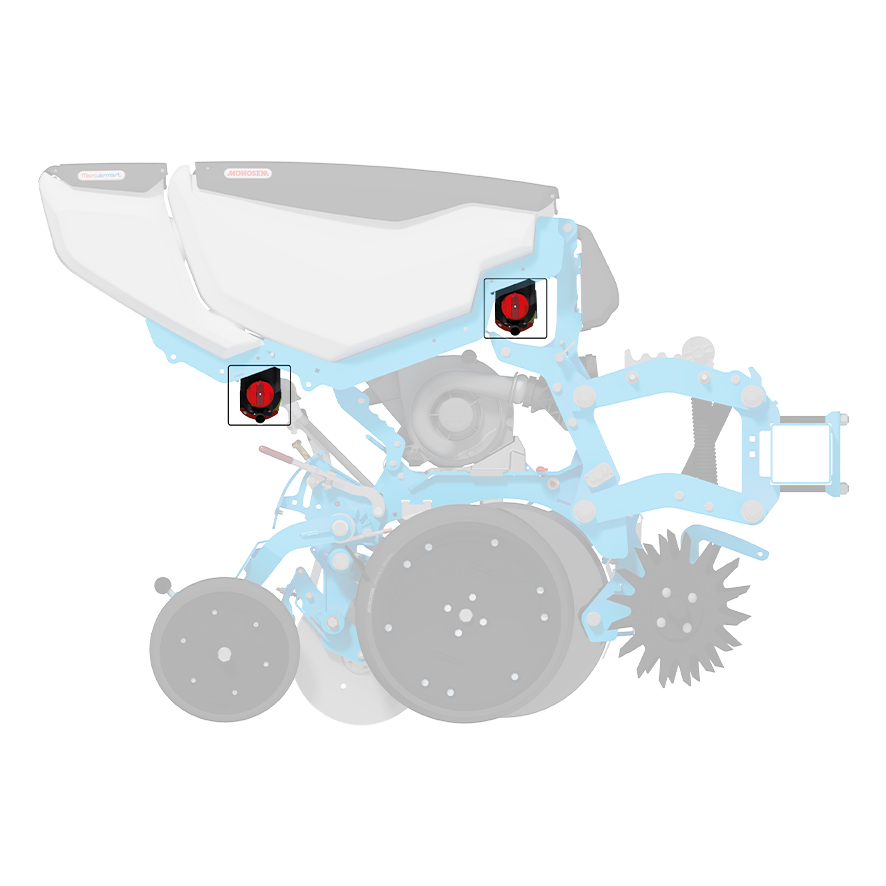

MicroSmart hopper:

With one 20L MicroSmart hopper per row, microgranular products are applied very close to seeds. The new hopper design enables 2 to 35kg/ha to be metered accurately when applying standard working speeds, products and row spacing.

MicroSmart microgranulator:

This unit is the core of the MicroSmart system, providing row-by-row application of microgranules and section-control. Microgranules can be changed easily and tool-free using two distribution screws.

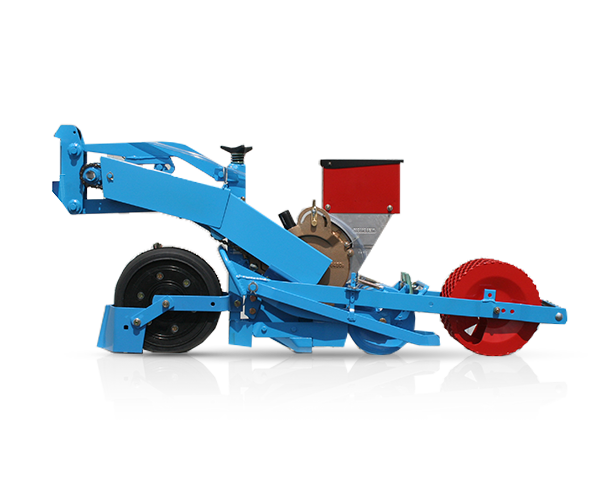

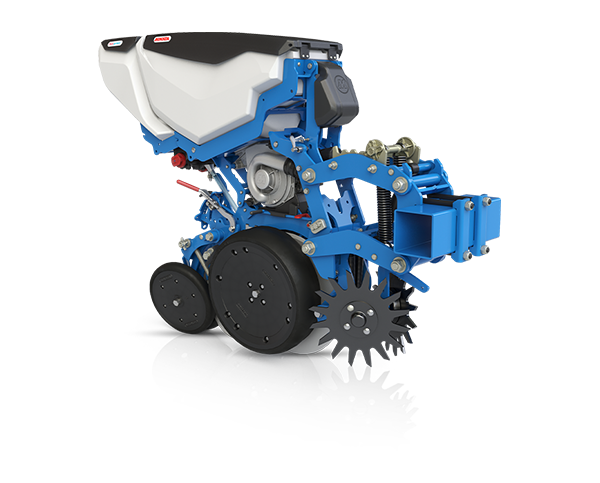

Seed hopper:

The capacity of the translucent plastic hopper has been increased to 70L. 70L equates to 160,000 maize seeds, or over 3 doses. This saves both time and effort.

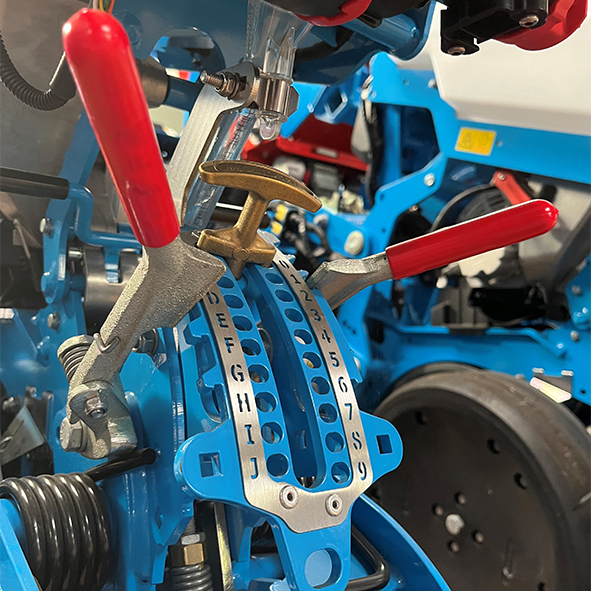

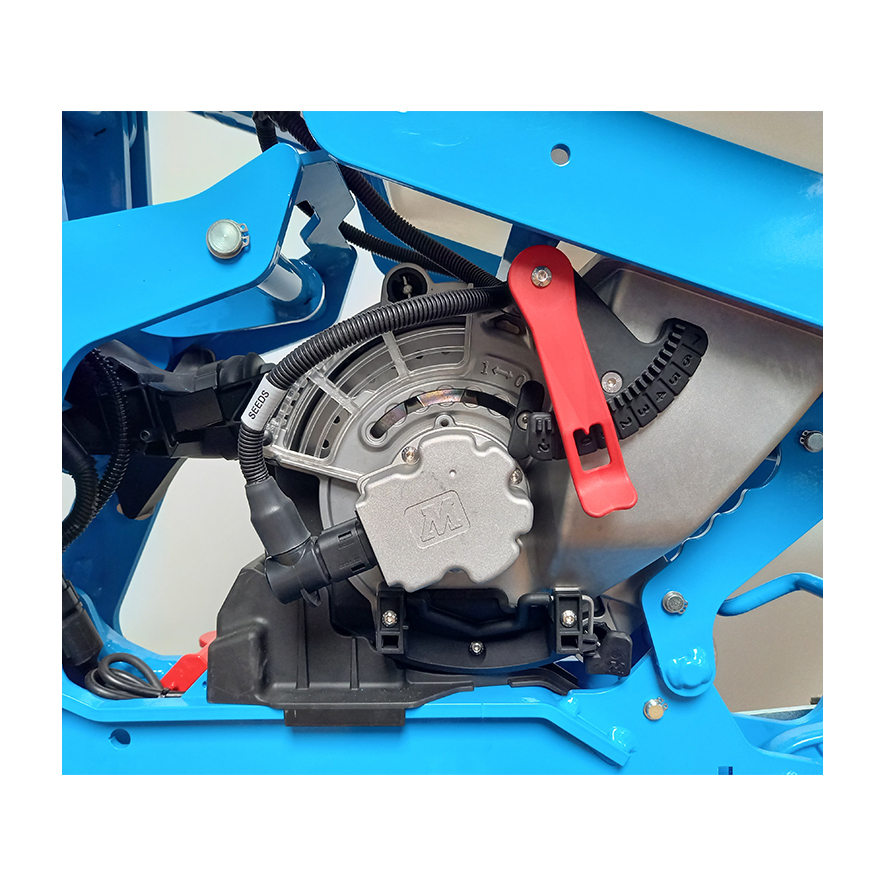

Planting adjustments:

Planting settings are adjusted using levers and notched scales that are easy to spot and quick to operate. These simplified adjustment mechanisms offer significant time savings.

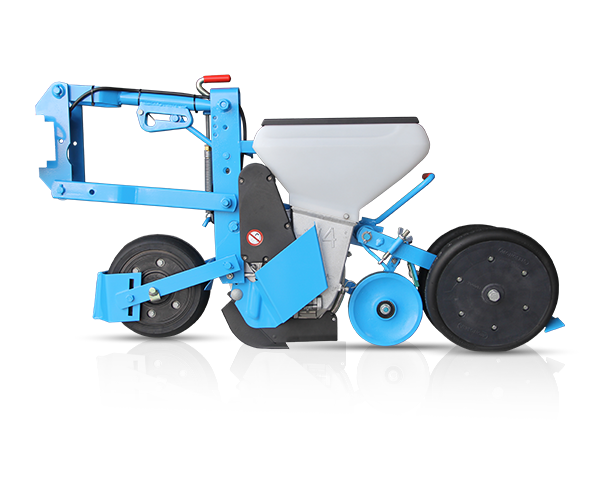

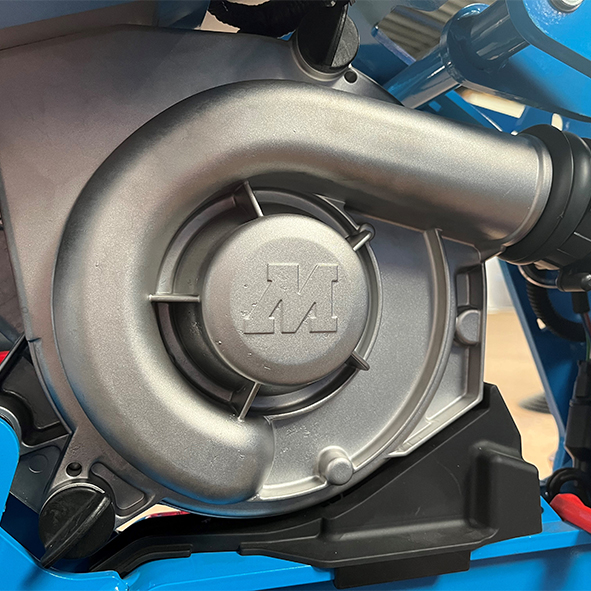

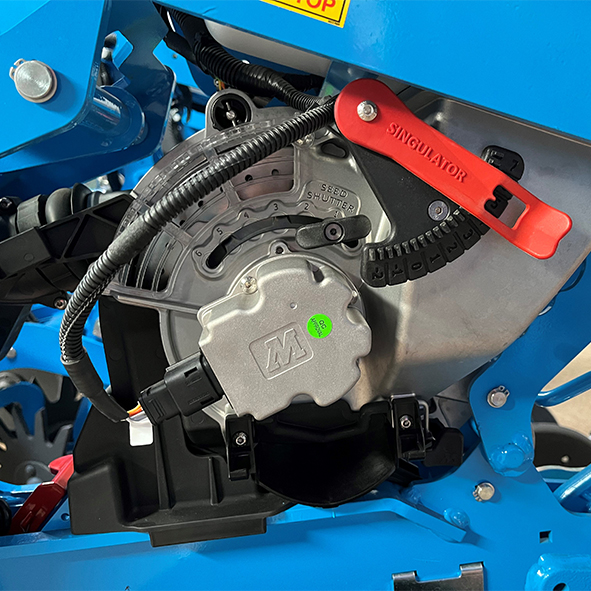

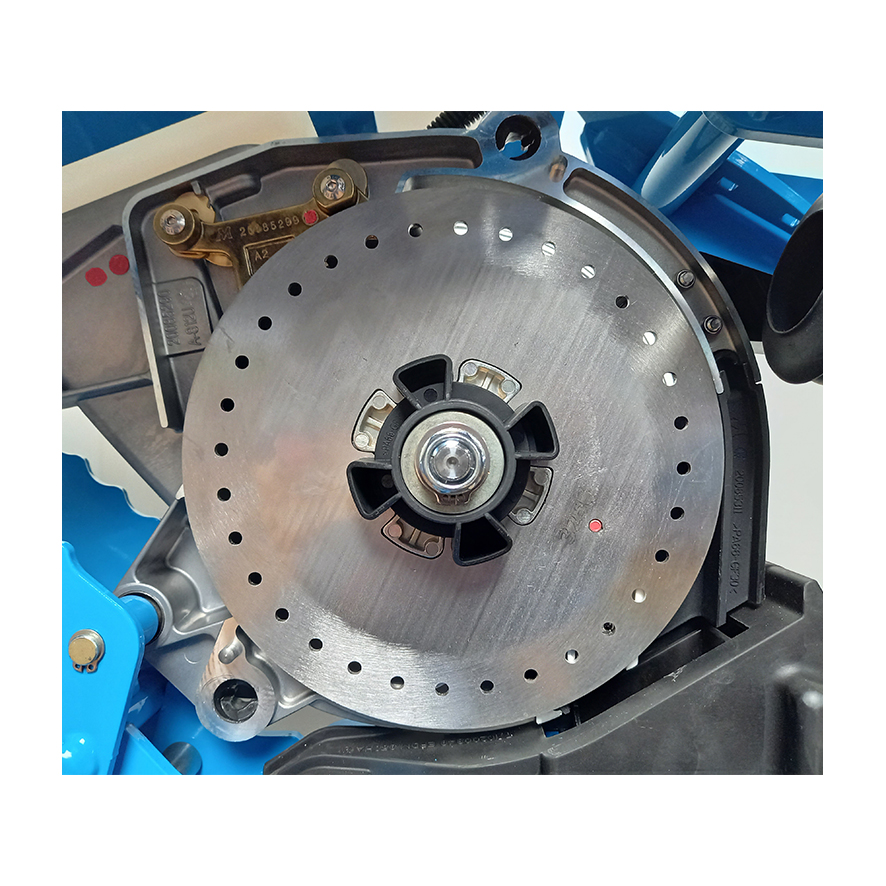

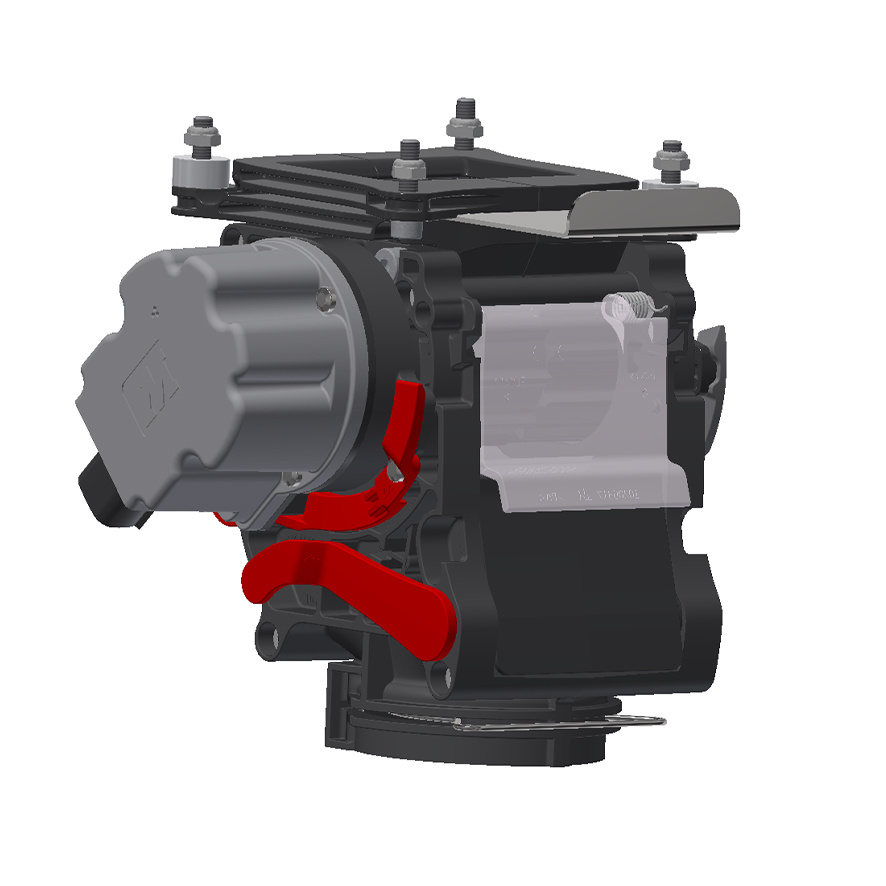

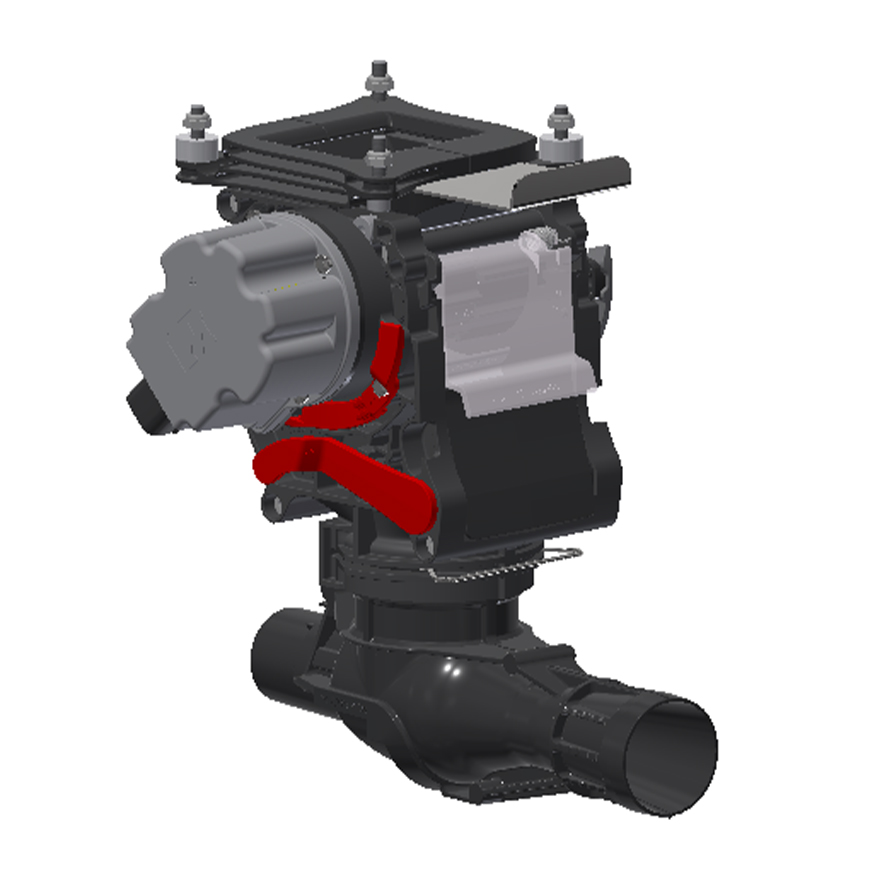

New metering box

The ValoTerra metering box is vacuum-operated, which is the best technology for planting the most diverse possible range of seeds at all speeds. The box is designed to be fully sealed with no leaks or loss of vacuum, which means that seeds remain attached to the disc at speeds of up to 18 kph. Performance, versatility and precision are combined in this new metering box.

Emptying the box

The metering box is quick and easy to empty. It is equipped with an integrated emptying chute and the seed supply can also be isolated using an adjustable shutter.

An electrically driven box:

As well as being fully leak-proof, the new metering box is equipped with an electric drive unit in the seed disc shaft enabling precision planting at higher speeds.

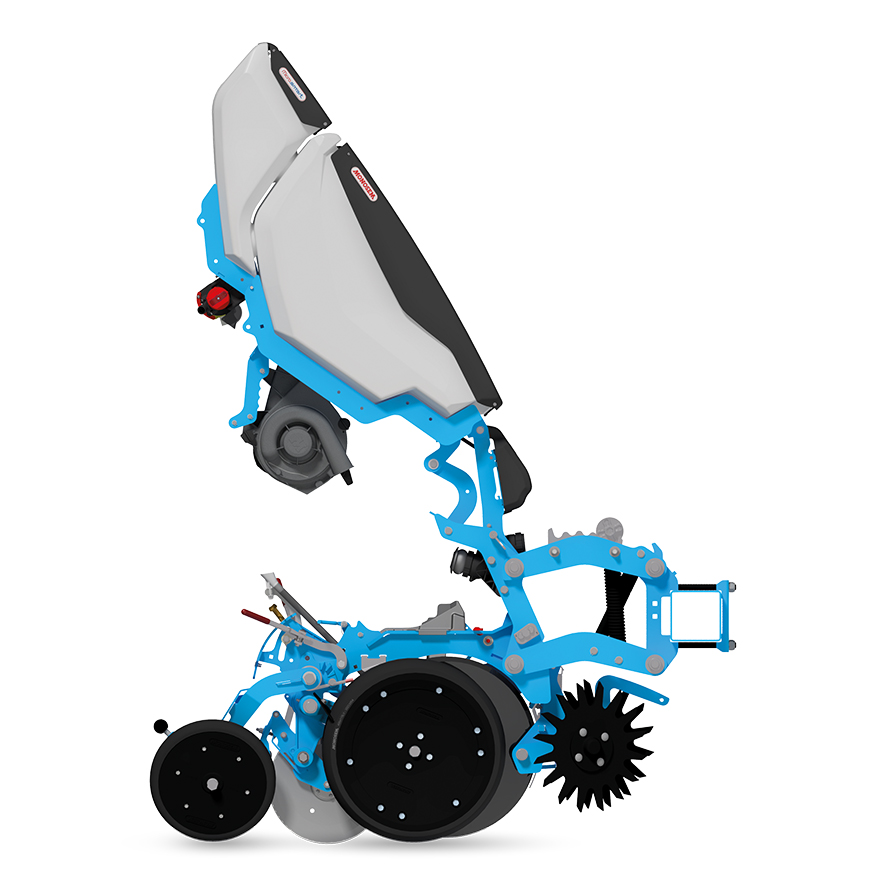

Adjustable closing wheels:

The ValoTerra's pressure- and angle-adjustable closing wheels close the furrow perfectly. They can be adapted to suit your field's physical conditions.

Pro wheel:

The ValoTerra's Pro wheel with an impressive 295mm diameter boasts unrivalled seed pressing.

It is pressure-adjustable and retractable up to a height of 4cm, allowing it to adapt to all conditions. Superior seed placement quality and improved shoot emergence both come courtesy of the new ValoTerra Pro wheel.

An optional flexible Pro wheel is also available for damp or stony soil.

An optional cast-iron Pro wheel is available for very low-till conditions.

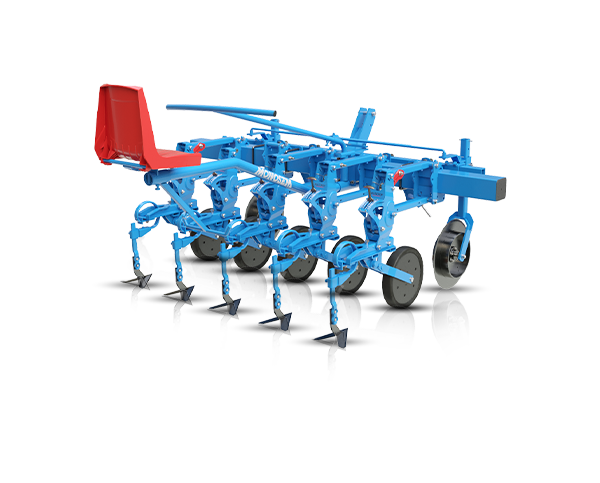

Gauge wheels:

450mm diameter, 115mm width, unprecedented stability.

- Increased load-bearing capacity

- Negotiate obstacles smoothly offering greater stability

- No mud spatter

- Largest diameter on the market

- Reduced soil marking

Double opener discs:

450mm diameter, unprecedented versatility.

- Very high penetration capacity in all conditions (reduced angle of attack)

- No mud spatter

- Reduced angle of attack

- Largest diameter on the market

Trash wheels (or clod remover):

The highly versatile trash wheels supplied as standard clear the furrow of plant debris and clods of earth. 8 height settings in 15mm increments – quick and easy to adjust tool-free using a cross-shaped stop.

Pressure springs:

In addition to its heavyweight design, the ValoTerra unit is equipped with pressure springs enabling unit pressure to be adjusted according to planting conditions. The ValoTerra unit offers ground pressure of up to 325kg depending on unit configuration and hopper filling levels. Pressure can be adjusted by 30kg increments (4 notches).

Monoshox shock absorber:

In addition to the ValoTerra unit's heavyweight design ensuring stability, precision and consistent planting, the Monoshox shock absorber compensates for bumps in the soil. This ensures that planting precision and depth consistency remain optimal even in challenging conditions.

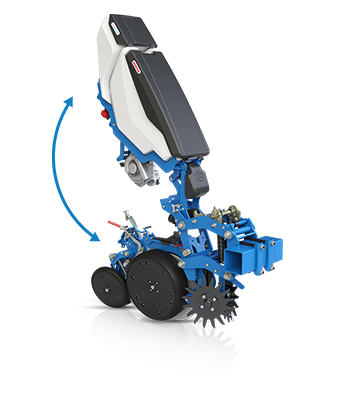

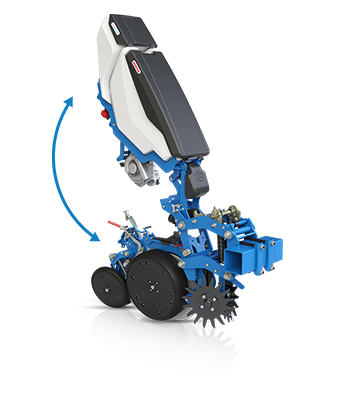

Smart Access:

SmartAccess, the raising system patented by Monosem that helps you maintain and service your units.

ULTIMATE

In the Ultimate version, the conveyor and chute can be swapped very quickly.

With one 20L MicroSmart hopper per row, microgranular products are applied very close to seeds. The new hopper design enables 2 to 35kg/ha to be metered accurately when applying standard working speeds, products and row spacing.

With one 20L MicroSmart hopper per row, microgranular products are applied very close to seeds. The new hopper design enables 2 to 35kg/ha to be metered accurately when applying standard working speeds, products and row spacing.

This unit is the core of the MicroSmart system, providing row-by-row application of microgranules and section-control. Microgranules can be changed easily and tool-free using two distribution screws.

This unit is the core of the MicroSmart system, providing row-by-row application of microgranules and section-control. Microgranules can be changed easily and tool-free using two distribution screws.

The capacity of the translucent plastic hopper has been increased to 70L. 70L equates to 160,000 maize seeds, or over 3 doses. This saves both time and effort.

The capacity of the translucent plastic hopper has been increased to 70L. 70L equates to 160,000 maize seeds, or over 3 doses. This saves both time and effort.

Planting settings are adjusted using levers and notched scales that are easy to spot and quick to operate. These simplified adjustment mechanisms offer significant time savings.

Planting settings are adjusted using levers and notched scales that are easy to spot and quick to operate. These simplified adjustment mechanisms offer significant time savings.

The ValoTerra metering box is vacuum-operated, which is the best technology for planting the most diverse possible range of seeds at all speeds. The box is designed to be fully sealed with no leaks or loss of vacuum, which means that seeds remain attached to the disc at speeds of up to 18 kph. Performance, versatility and precision are combined in this new metering box.

The ValoTerra metering box is vacuum-operated, which is the best technology for planting the most diverse possible range of seeds at all speeds. The box is designed to be fully sealed with no leaks or loss of vacuum, which means that seeds remain attached to the disc at speeds of up to 18 kph. Performance, versatility and precision are combined in this new metering box.

The metering box is quick and easy to empty. It is equipped with an integrated emptying chute and the seed supply can also be isolated using an adjustable shutter.

The metering box is quick and easy to empty. It is equipped with an integrated emptying chute and the seed supply can also be isolated using an adjustable shutter.

As well as being fully leak-proof, the new metering box is equipped with an electric drive unit in the seed disc shaft enabling precision planting at higher speeds.

As well as being fully leak-proof, the new metering box is equipped with an electric drive unit in the seed disc shaft enabling precision planting at higher speeds.

The ValoTerra's pressure- and angle-adjustable closing wheels close the furrow perfectly. They can be adapted to suit your field's physical conditions.

The ValoTerra's Pro wheel with an impressive 295mm diameter boasts unrivalled seed pressing.

The ValoTerra's Pro wheel with an impressive 295mm diameter boasts unrivalled seed pressing.

It is pressure-adjustable and retractable up to a height of 4cm, allowing it to adapt to all conditions. Superior seed placement quality and improved shoot emergence both come courtesy of the new ValoTerra Pro wheel.

An optional flexible Pro wheel is also available for damp or stony soil.

An optional cast-iron Pro wheel is available for very low-till conditions.

450mm diameter, 115mm width, unprecedented stability.

450mm diameter, 115mm width, unprecedented stability.

- Increased load-bearing capacity

- Negotiate obstacles smoothly offering greater stability

- No mud spatter

- Largest diameter on the market

- Reduced soil marking

450mm diameter, unprecedented versatility.

450mm diameter, unprecedented versatility.

- Very high penetration capacity in all conditions (reduced angle of attack)

- Reduced angle of attack

- Largest diameter on the market

The highly versatile trash wheels supplied as standard clear the furrow of plant debris and clods of earth. 8 height settings in 15mm increments – quick and easy to adjust tool-free using a cross-shaped stop.

The highly versatile trash wheels supplied as standard clear the furrow of plant debris and clods of earth. 8 height settings in 15mm increments – quick and easy to adjust tool-free using a cross-shaped stop.

In addition to its heavyweight design, the ValoTerra unit is equipped with pressure springs enabling unit pressure to be adjusted according to planting conditions. The ValoTerra unit offers ground pressure of up to 325kg depending on unit configuration and hopper filling levels. Pressure can be adjusted by 30kg increments (4 notches).

In addition to its heavyweight design, the ValoTerra unit is equipped with pressure springs enabling unit pressure to be adjusted according to planting conditions. The ValoTerra unit offers ground pressure of up to 325kg depending on unit configuration and hopper filling levels. Pressure can be adjusted by 30kg increments (4 notches).

In addition to the ValoTerra unit's heavyweight design ensuring stability, precision and consistent planting, the Monoshox shock absorber compensates for bumps in the soil. This ensures that planting precision and depth consistency remain optimal even in challenging conditions.

In addition to the ValoTerra unit's heavyweight design ensuring stability, precision and consistent planting, the Monoshox shock absorber compensates for bumps in the soil. This ensures that planting precision and depth consistency remain optimal even in challenging conditions.

SmartAccess, the raising system patented by Monosem that helps you maintain and service your units.

SmartAccess, the raising system patented by Monosem that helps you maintain and service your units.

ULTIMATE

In the Ultimate version, the conveyor and chute can be swapped very quickly.

- Optimized seed/input densities and lean metering

- A generator capable of supplying 5.6 kW

- Technically simple: no battery

The different types of distributions

METERING SYSTEM

Benefits of the Ultimate

METERING SYSTEMSETTING NEW STANDARDS OF EXCELLENCE FOR PRECISION PLANTERS

Besides offering improved performance, it has been specifically designed to be easy to use, versatile and heavy-duty. Its electric motor and user-friendly design offer a great combination of air-tightness and vacuum, providing utmost planting precision at high speed.

With its electric motor in the seed disc shaft, floating insert allowing the seed disc to rotate more easily and new 3-toothed singulator, this new patented metering box sets new standards for precision and efficiency. It boasts an energy-efficient system, and what's more, maize seeds remain attached at speeds of up to 18 kph.

With its electric motor in the seed disc shaft, floating insert allowing the seed disc to rotate more easily and new 3-toothed singulator, this new patented metering box sets new standards for precision and efficiency. It boasts an energy-efficient system, and what's more, maize seeds remain attached at speeds of up to 18 kph.

Since every last seed planted offers potential to boost yield, it's now possible to monitor metering quality using the viewing window, ISOBUS terminal or smartphone app. Easily adjustable precision settings ensure highly accurate metering.

Since every last seed planted offers potential to boost yield, it's now possible to monitor metering quality using the viewing window, ISOBUS terminal or smartphone app. Easily adjustable precision settings ensure highly accurate metering.

It's now possible to switch crops in less than a minute per row:

It's now possible to switch crops in less than a minute per row:

- Only the seed disc needs changing

- Fixed agitator and seed singulator

- Quick to empty with the integrated chute

- 2 integrated quarter-turn handles in the cover

The ValoTerra metering box is vacuum-operated, which is the best technology for planting the most diverse possible range of seeds at all speeds. Maize, Sunflower, Rapeseed, Soya Beans, Sugarbeet, etc.

The ValoTerra metering box is vacuum-operated, which is the best technology for planting the most diverse possible range of seeds at all speeds. Maize, Sunflower, Rapeseed, Soya Beans, Sugarbeet, etc.

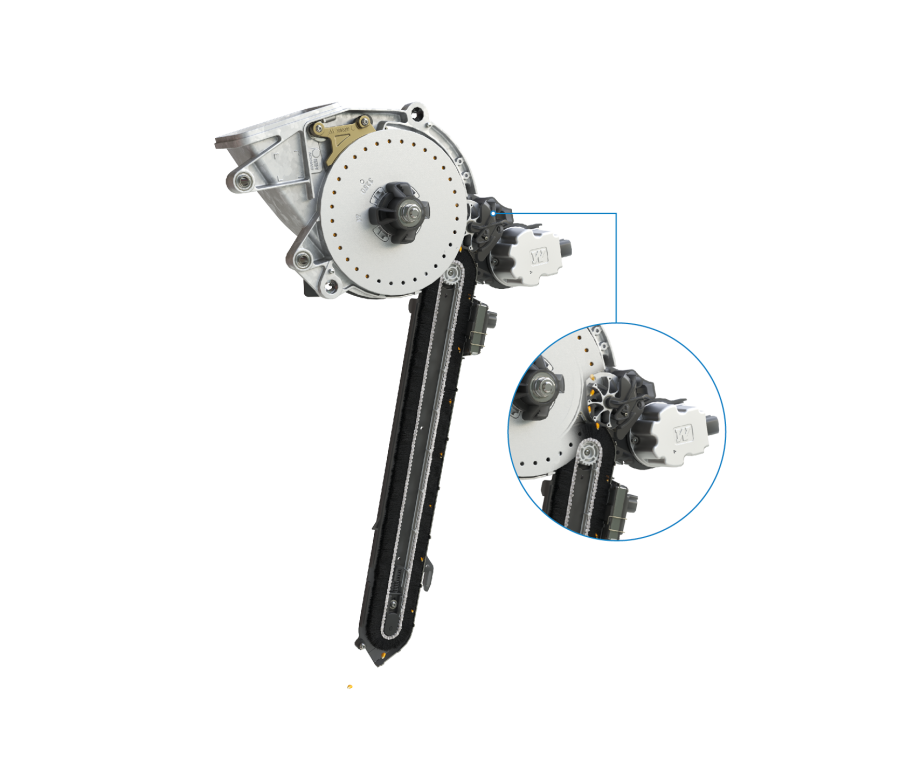

Active Seed Guidance (ASG)

THE NEW SEED GUIDANCE SYSTEM IS USED TO APPLY OUR ZERO-GRAVITY CONCEPT.

Our active guidance system controls all stages of the seeds' journey, from the seed disc to the cellular loading wheel and finally, the conveyor outlet.

The seed ejection speed is proportionate to the tractor's working speed, avoiding any roll back, and spacing in the furrow is kept consistent on both flat and uneven ground.

This means that speed is no longer an issue, since each seed is positioned precisely at speeds of 4 to 18 km/h.

Each seed is supplied to the Monosem-patented cellular loading wheel, which then inserts it into the brush conveyor using a system of guide rods.

The system is designed to ensure that seeds are inserted precisely in the brush before being carried down for placement in the furrow.

The conveyor belt for the brush is grooved to ensure optimal alignment, perfect rotation, and minimal wear: a new Monosem-patented innovation.

The rotating brush conveyor guides seeds to the furrow at a rate proportionate to the tractor's working speed, eliminating any bumps and vibrations.

This is the ideal solution for ensuring accurate and consistent seed placement in the furrow!

BENEFITS OF THE VALOTERRA

CONVENIENCE & TIME SAVINGS

- Switching crops takes less than a minute per row

- The seed flow can be isolated to access the box

- Easy to empty

- ULTIMATE

- With the ValoTerra Ultimate, it takes less than two minutes per row to switch from the belt system to the chute system

BENEFITS OF THE VALOTERRA

PERFORMANCE & PRODUCTIVITY

-

Pneumatic metering and smooth discs ensure perfect distribution for a maximum range of seeds and crops

-

Optimized suction for wider working ranges

-

Patented system for reducing the torque required to drive the disc independently of the vacuum level

why choose the

Valoterra planter ?

Revolutionary precision

New metering box patented by Monosem

A benchmark in planting

Largest gauge wheels and opener discs on the market

Unrivalled ease of use

A unique lifting hopper system

why choose the

Valoterra planter ?

Revolutionary precision

New metering box patented by Monosem

A benchmark in planting

Largest gauge wheels and opener discs on the market

Unrivalled ease of use

A unique lifting hopper system

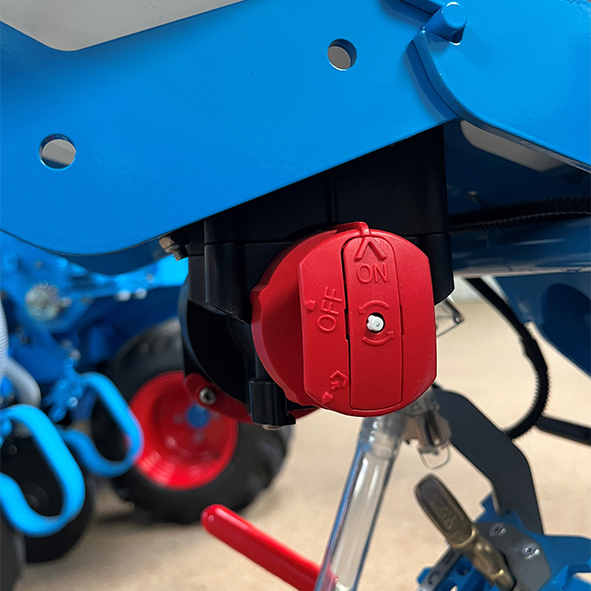

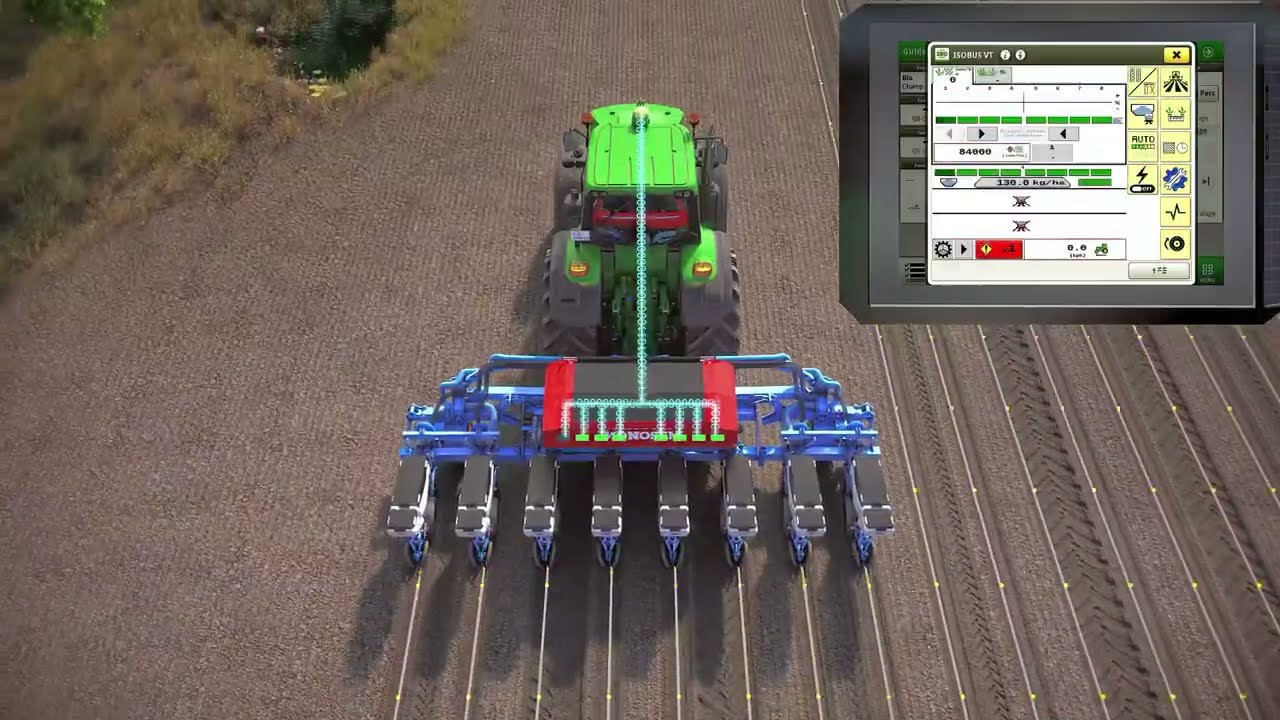

This equipment enables you to control your inputs row by row using Monosem Smart Motors. The section-control feature supplied as standard on an ISOBUS terminal prevents any overlap when applying your inputs.

- MicroSmart capacity: 20L

- Easy to calibrate with flexible pipes

- Ergonomic ON/OFF/EMPTY control dial

- Color-coded distribution screw, visible to the user

- Quarter-turn opening mechanism for changing screws or quick maintenance

- Convenient loading height for operator comfort and safety

The MicroSmart system can be accessed easily using the ValoTerra's raising system. All MicroSmart components are positioned at a convenient height and can be removed in seconds offering unrivalled ease of use.

The MicroSmart system can be accessed easily using the ValoTerra's raising system. All MicroSmart components are positioned at a convenient height and can be removed in seconds offering unrivalled ease of use.

Two types of microgranules can be applied simultaneously per row using the two independent microgranulators.*

Two types of microgranules can be applied simultaneously per row using the two independent microgranulators.*

*Available soon

- Configuration A: 20L MicroSmart hopper + 70L seed hopper

- Configuration B*: 20L MicroSmart hopper + 15L MicroSmart hopper + 55L seed hopper

*Available soon

Using a terminal, you can manage row cut-offs and variable rates for your MicroSmart units by GPS, enabling up to 7% savings on inputs depending on the product.

Using a terminal, you can manage row cut-offs and variable rates for your MicroSmart units by GPS, enabling up to 7% savings on inputs depending on the product.

Microgranules can be sent to 4 different lines* during metering using the multi-line metering system. Products can now be metered ahead of, behind, on the surface and around seeds. Since each microgranule type comes with its own specific optimal positioning guidelines, MicroSmart gives farmers the flexibility they need.

Microgranules can be sent to 4 different lines* during metering using the multi-line metering system. Products can now be metered ahead of, behind, on the surface and around seeds. Since each microgranule type comes with its own specific optimal positioning guidelines, MicroSmart gives farmers the flexibility they need.

*Available soon

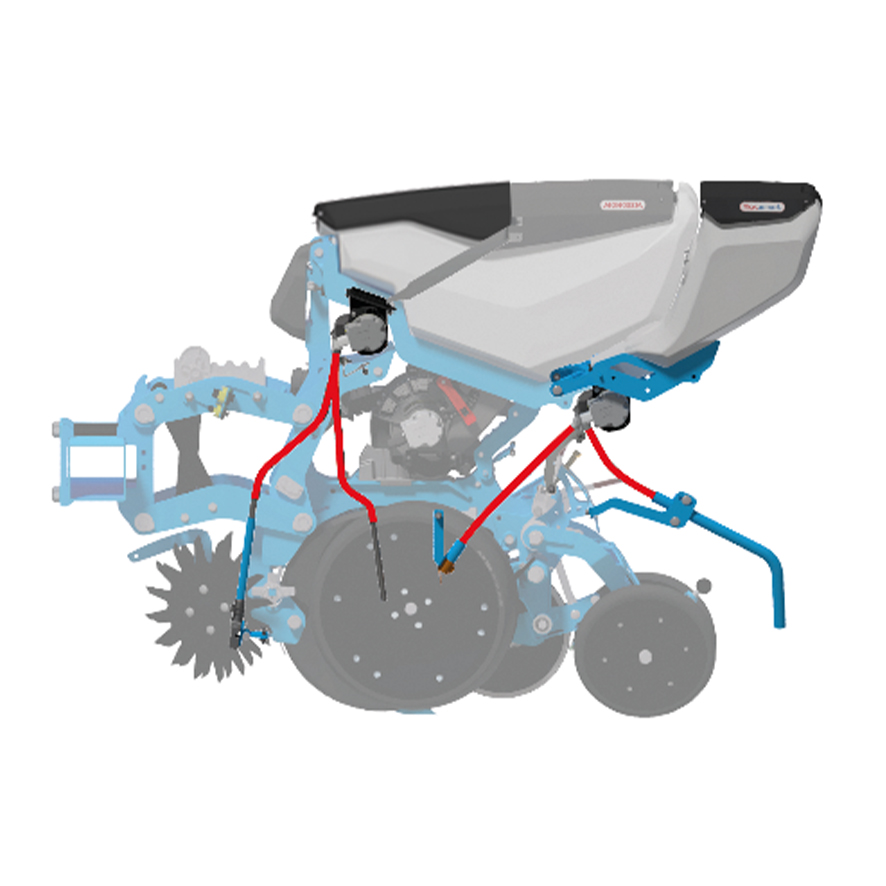

FertiSmart: MONOSEM SMART SOLUTIONS APPLIED TO FERTILIZATION

The new FertiSmart fertilizer distribution unit, exclusively designed by Monosem, is able to apply dry fertilizer with row-by-row section-control.

Its revolutionary design guarantees accurate application and a high gravity-based drop rate of up to 600kg/ha.

The FertiSmart unit provides optimum performance whatever the terrain, slopes included, even where demanding fertilizers are concerned, thus overcoming the limitations of current technologies.

Optimized fertilization: variable rate fertilizer application and row-by-row section-control

Optimized fertilization: variable rate fertilizer application and row-by-row section-control

- Precision application in all conditions, including on sloping land

- Consistent flow: its fluted metering cylinders can handle any fertilizer regardless of its physical properties

- The flow rate can be tailored to your requirements: up to 600kg/ha by gravity

- Promotes organic farming: compatible with granulated organic fertilizers

The FertiSmart distribution unit is designed to be highly effective and versatile. Its 360° gravity-based and pumped outlets contribute to this by ensuring an accurate and even flow.

Moreover, its fluted metering cylinders optimize system performance whatever the physical properties of the fertilizers applied. The distribution units' precision and performance remain unchanged on sloping land.

2 possible configurations:

2 possible configurations:

- MSM: One motor per row. Allows you to tap the full potential of the FertiSmart solution equipped for section-control and row-by-row control.

- ISM: One motor for several rows. This allows you to choose the right configuration for your working practices and requirements

- The motor locks in a quarter turn.

- The flow rate can be adjusted per distribution unit using a control dial. Optimizes flow rate and is unaffected by fertilizers' physical properties.

- It's easy to connect the distribution unit. Unrivalled time savings and ease of use.

- Variable width control across the entire working width

- Automatic row cut-off by GPS

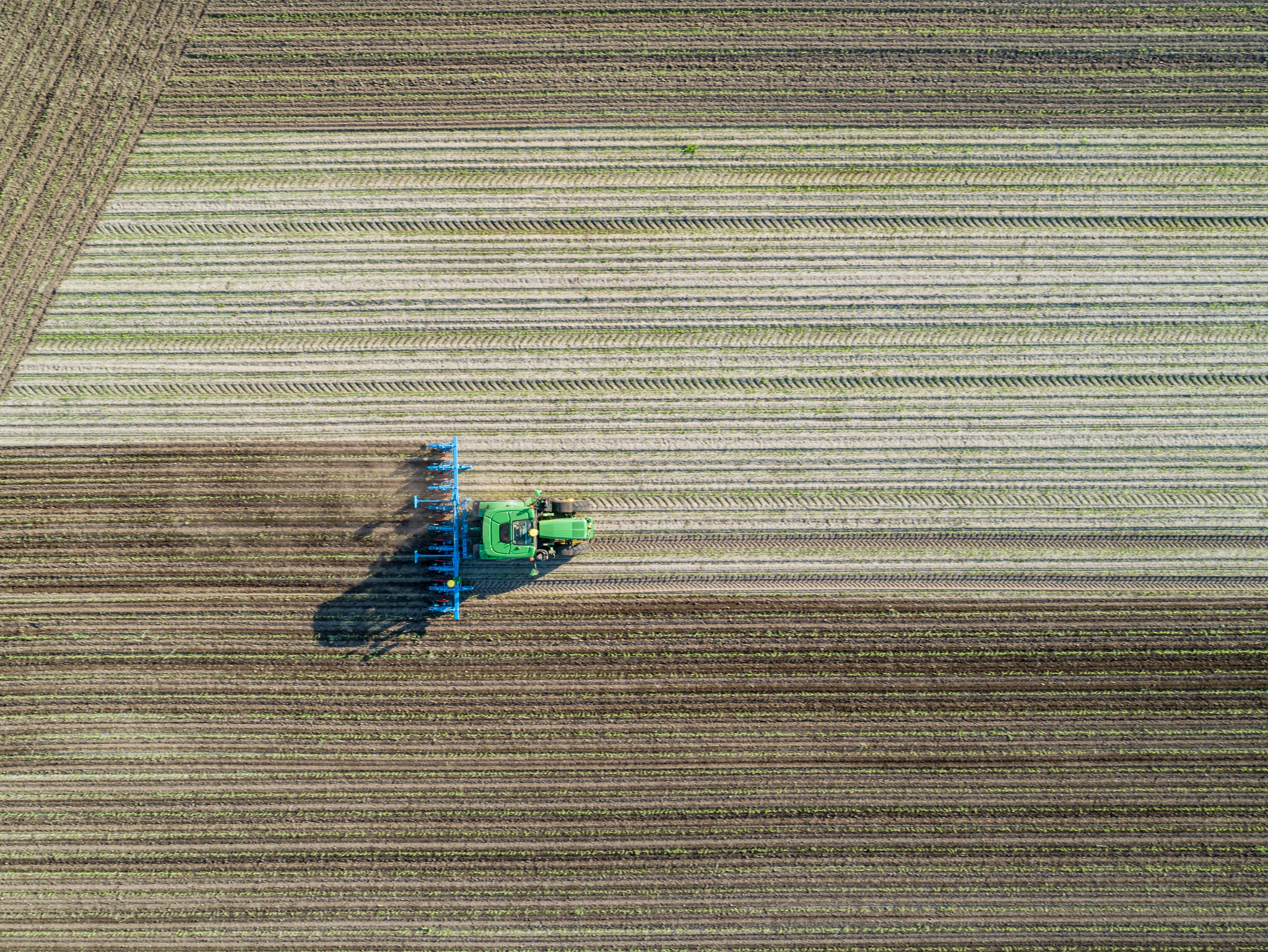

EXPERIENCE the VALOTERRA in action

tried AND TESTED

IN THE FIELD

Tested, approved and universally recognized

All key stakeholders are unanimous in their view that Monosem has set the new benchmark for precision planting.

Speed is no longer

an issue

Optimal emergence at all speeds

With its new brush-based seed guidance system, the ValoTerra Ultimate ensures optimal consistency of planting depth and seed spacing at speeds of 4 to 18 km/h, resulting in fast and uniform shoot emergence!

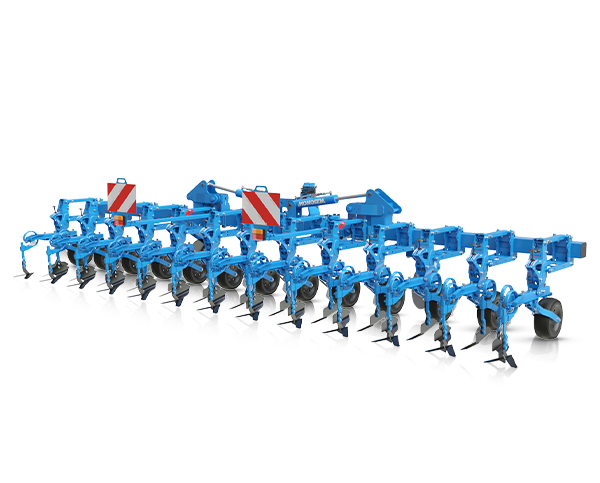

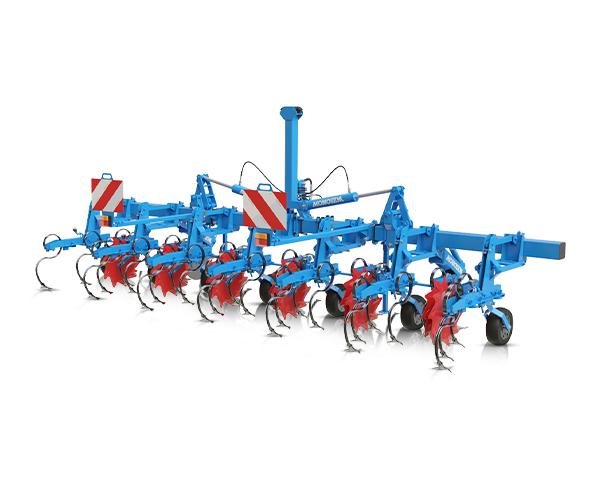

A WIDE RANGE OF FRAMES

Since its launch, the ValoTerra has been available in 4 different configurations ranging from 6 to 12 rows.

VALOTERRA

FEATURES

CROP TYPE

Maize

Sugarbeet

Sunflower

Rapeseed

Soya Beans

etc.

TILLAGE

Traditional

Low Till

No Till

NUMBER OF ROWS

6 to 12 rows

INTER-ROW SPACING

45cm to 80cm

DRIVE

Mechanical

Electrical

CROP TYPE

Maize

Sugarbeet

Sunflower

Rapeseed

Soya Beans

etc.

TILLAGE

Traditional

Low Till

No Till

NUMBER OF ROWS

6 to 12 rows

INTER-ROW SPACING

45cm to 80cm

DRIVE

Electrical

are you INTERESTED?

Don't delay a second longer

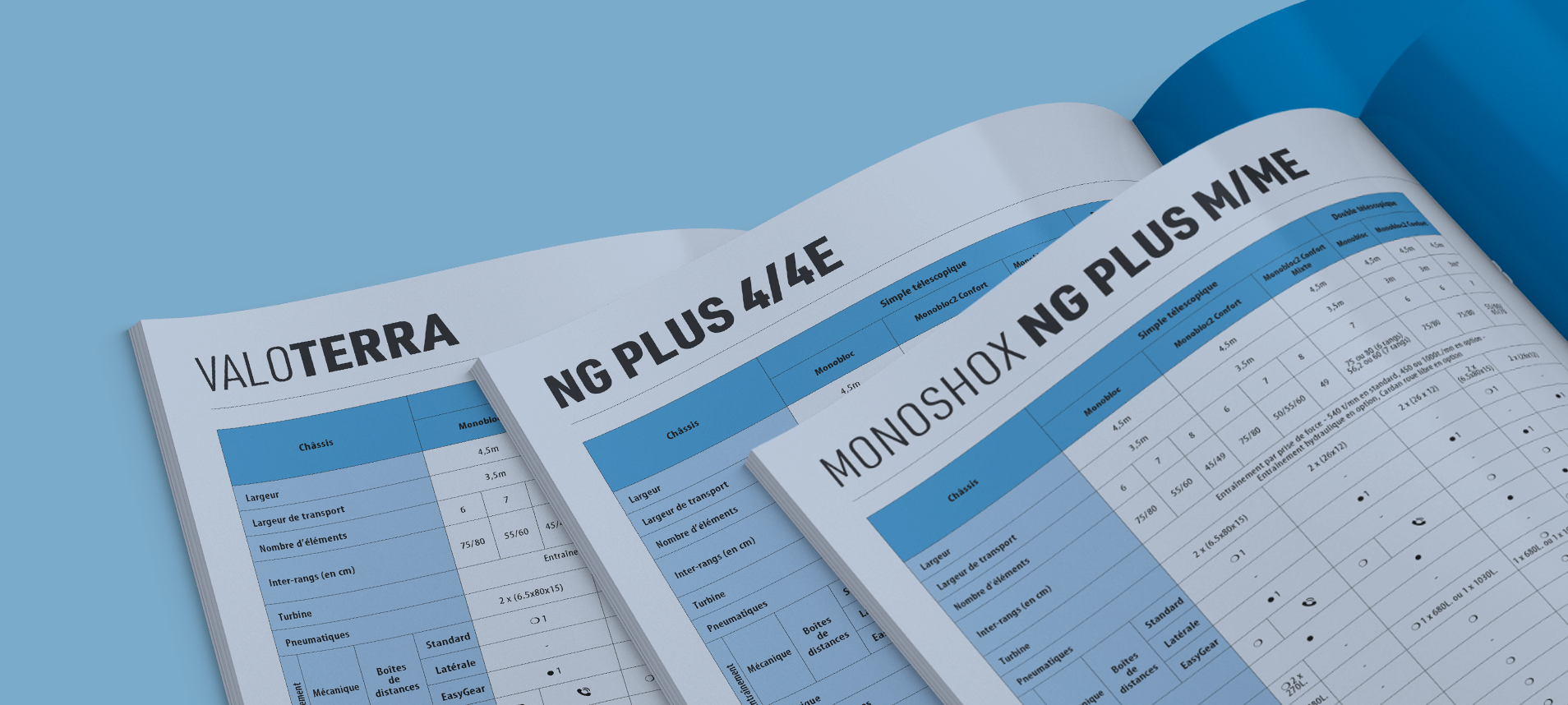

Documents

Download our manuals and brochures to find out more about the VALOTERRA